Page 44 - machining_titanium_05_2019

P. 44

MILLING TITANIUM The mill has 6 teeth, hence feed speed Vf=0.45 × 6 × 310=837 (mm/min) or approx. 33 ipm.

Maximum depth of cut (DOC) apmax (the catalogue data) for the mill is 0.8 mm (.0031 in).

Necessary ramping angle for milling lengthwise

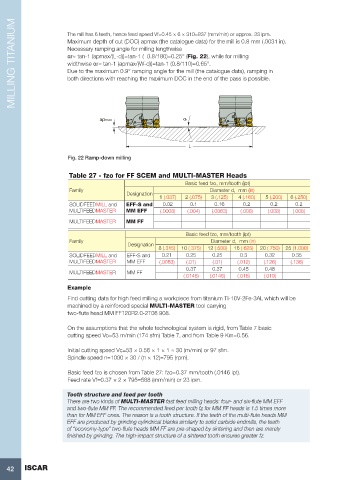

αr≈ tan-1 (apmax/(L-d))=tan-1 ( 0.8/180)=0.25° (Fig. 22), while for milling

widthwise αr≈ tan-1 (apmax/(W-d))=tan-1 (0.8/110)=0.65°.

Due to the maximum 0.9° ramping angle for the mill (the catalogue data), ramping in

both directions with reaching the maximum DOC in the end of the pass is possible.

apmax αr

L

Fig. 22 Ramp-down milling

Table 27 - fzo for FF SCEM and MULTI-MASTER Heads

Basic feed fzo, mm/tooth (ipt)

Family Diameter d, mm (in)

Designation

1 (.037) 2 (.075) 3 (.125) 4 (.160) 5 (.200) 6 (.250)

SOLIDFEEDMILL and EFF-S and 0.02 0.1 0.16 0.2 0.2 0.2

MULTIFEEDMASTER MM EFF (.0008) (.004) (.0063) (.008) (.008) (.008)

MULTIFEEDMASTER MM FF

Basic feed fzo, mm/tooth (ipt)

Family Diameter d, mm (in)

Designation

8 (.315) 10 (.375) 12 (.500) 16 (.625) 20 (.750) 25 (1.000)

SOLIDFEEDMILL and EFF-S and 0.21 0.25 0.25 0.3 0.32 0.35

MULTIFEEDMASTER MM EFF (.0083) (.01) (.01) (.012) (.126) (.138)

0.37 0.37 0.45 0.48

MULTIFEEDMASTER MM FF

(.0146) (.0146) (.018) (.019)

Example

Find cutting data for high feed milling a workpiece from titanium Ti-10V-2Fe-3Al, which will be

machined by a reinforced special MULTI-MASTER tool carrying

two-flute head MM FF120R2.0-2T08 908.

On the assumptions that the whole technological system is rigid, from Table 7 basic

cutting speed Vo=53 m/min (174 sfm) Table 7, and from Table 9 Km=0.56.

Initial cutting speed Vc=53 × 0.56 × 1 × 1 ≈ 30 (m/min) or 97 sfm.

Spindle speed n=1000 × 30 / (π × 12)=795 (rpm).

Basic feed fzo is chosen from Table 27: fzo=0.37 mm/tooth (.0146 ipt).

Feed rate Vf=0.37 × 2 × 795=588 (mm/min) or 23 ipm.

Tooth structure and feed per tooth

There are two kinds of MULTI-MASTER fast feed milling heads: four- and six-flute MM EFF

and two-flute MM FF. The recommended feed per tooth fz for MM FF heads is 1.5 times more

than for MM EFF ones. The reason is a tooth structure. If the teeth of the multi-flute heads MM

EFF are produced by grinding cylindrical blanks similarly to solid carbide endmills, the teeth

of “economy-type” two-flute heads MM FF are pre-shaped by sintering and then are merely

finished by grinding. The high-impact structure of a sintered tooth ensures greater fz.

42 ISCAR