Page 47 - machining_titanium_05_2019

P. 47

Example

An aircraft engine builder has decided to apply trochoidal milling to rough machining

slots in an integrally bladed rotor. ISCAR’s 10 mm (0.394 in) dia. ECK-H7 7-flute

solid carbide endmill, made from carbide grade IC900, will be used under the

following averaged machining parameters: ap=16 mm (0.63 in), ae=1 mm (0.04 in). MILLING TITANIUM

Material – Ti-6Al-4V ELI. Operational stability is good. Find initial cutting data.

Assume that Ks=1 (stable cutting).

Basic cutting speed V0=65 m/min (213 sfm) (Table 8).

Km=1.1 (Table 9).

ae/d=1/10=0.1. Angle of engagement AE=36°, Ke=1.5 (Table 10).

From equation (1): initial cutting speed Vc=65×1.1×1.5×1=107 (m/min) or 352 sfm.

Spindle speed n=(1000×107)/(π×10)=

3406 (rpm).

Basic feed per tooth fzo=0.13 mm/tooth (0.0051 ipt) (Table 16).

Kf=0.78 (Table 17).

From equation (6): starting feed fz=0.13×1×0.78=0.1 (mm/tooth) or 0.004 ipt.

Feed rate Vf=0.1×7×3406=2384 (mm/min) (93.86 ipm).

Estimated metal removal rate Q=1.6×0.1×238.4=38.14 (cm³/min) (2.36 in³/min)

Slot

axis

vf

n

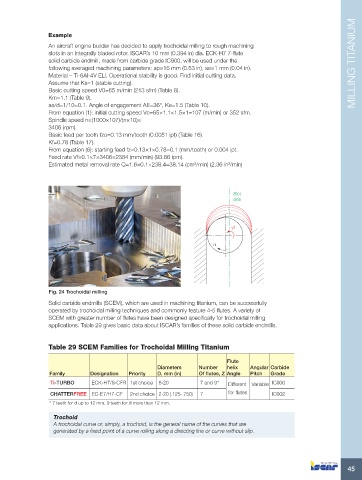

Fig. 24 Trochoidal milling

Solid carbide endmills (SCEM), which are used in machining titanium, can be successfully

operated by trochoidal milling techniques and commonly feature 4-5 flutes. A variety of

SCEM with greater number of flutes have been designed specifically for trochoidal milling

applications. Table 29 gives basic data about ISCAR’s families of these solid carbide endmills.

Table 29 SCEM Families for Trochoidal Milling Titanium

Flute

Diameters Number helix Angular Carbide

Family Designation Priority D, mm (in) Of flutes, Z Angle Pitch Grade

Ti-TURBO ECK-H7/9-CFR 1st choice 6-20 7 and 9* Different Variable IC900

CHATTERFREE EC-E7/H7-CF 2nd choice 2-20 (.125-.750) 7 for flutes IC902

* 7 teeth for d up to 12 mm, 9 teeth for d more than 12 mm.

Trochoid

A trochoidal curve or, simply, a trochoid, is the general name of the curves that are

generated by a fixed point of a curve rolling along a directing line or curve without slip.

45