Page 54 - machining_titanium_05_2019

P. 54

DRILLING TITANIUM Initial Cutting Data In Drilling

Cutting Speed

In drilling titanium with coolant pressure up to 70 bar,

initial cutting speed Vc is found with the use of equation (9):

Vc=Vo×Km×Ks

(9)

Vo – basic cutting speed (Table 37)

Where:

Km – machinability factor (Table 9)

Ks – stability factor (1 for normal stability and 0.7-0.8

for unstable drilling and machining in unfavorable conditions)

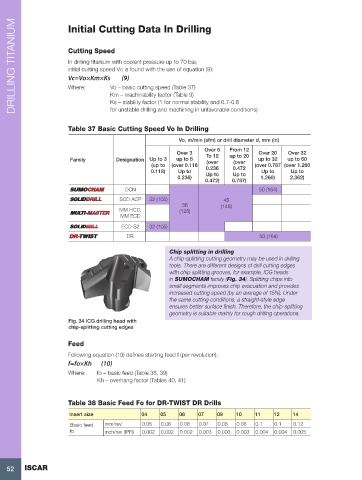

Table 37 Basic Cutting Speed Vo In Drilling

Vo, m/min (sfm) or drill diameter d, mm (in)

Over 6 From 12

Over 3 To 12 up to 20 Over 20 Over 32

Family Designation Up to 3 up to 6 (over (over up to 32 up to 60

(up to (over 0.118 (over 0.787 (over 1.260

0.118) Up to 0.236 0.472 Up to Up to

Up to

Up to

0.236) 1.260) 2.362)

0.472) 0.787)

DCN 50 (164)

SCD ACP 32 (105) 45

38 (148)

MM HCD, (125)

MM ECD

ECD-S2 32 (105)

DR 50 (164)

Chip splitting in drilling

A chip-splitting cutting geometry may be used in drilling

tools. There are different designs of drill cutting edges

with chip splitting grooves, for example, ICG heads

in SUMOCHAM family (Fig. 34). Splitting chips into

small segments improves chip evacuation and provides

increased cutting speed (by an average of 15%). Under

the same cutting conditions, a straight-style edge

ensures better surface finish. Therefore, the chip-splitting

geometry is suitable mainly for rough drilling operations.

Fig. 34 ICG drilling head with

chip-splitting cutting edges

Feed

Following equation (10) defines starting feed f (per revolution):

f=fo×Kh (10)

Where: fo – basic feed (Table 38, 39)

Kh – overhang factor (Tables 40, 41)

Table 38 Basic Feed Fo for DR-TWIST DR Drills

Insert size 04 05 06 07 09 10 11 12 14

Basic feed mm/rev 0.05 0.06 0.06 0.07 0.08 0.08 0.1 0.1 0.12

fo inch/rev (IPR) 0.002 0.002 0.002 0.003 0.003 0.003 0.004 0.004 0.005

52 ISCAR