Page 55 - machining_titanium_05_2019

P. 55

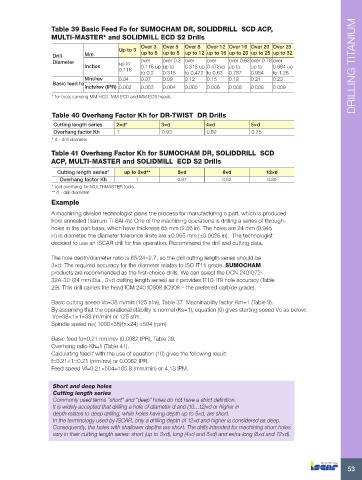

Table 39 Basic Feed Fo for SUMOCHAM DR, SOLIDDRILL SCD ACP,

MULTI-MASTER* and SOLIDMILL ECD S2 Drills

Over 3 Over 5 Over 8 Over 12 Over 16 Over 20 Over 25

Up to 3

Drill Mm up to 5 up to 8 up to 12 up to 16 up to 20 up to 25 up to 32

Diameter up to over over 0.2 over over over 0.63 over 0.78 over

Inches 0.118 up up to 0.315 up 0.472up up to up to 0.984 up DRILLING TITANIUM

0.118

to 0.2 0.315 to 0.472 to 0.63 0.787 0.984 to 1.26

Mm/rev 0.04 0.07 0.09 0.12 0.15 0.19 0.21 0.23

Basic feed fo

Inch/rev (IPR) 0.002 0.003 0.004 0.005 0.006 0.008 0.008 0.009

* for tools carrying MM HCD, MM ECD and MM ECS heads

Table 40 Overhang Factor Kh for DR-TWIST DR Drills

Cutting length series 2×d* 3×d 4×d 5×d

Overhang factor Kh 1 0.93 0.82 0.75

* d - drill diameter

Table 41 Overhang Factor Kh for SUMOCHAM DR, SOLIDDRILL SCD

ACP, MULTI-MASTER and SOLIDMILL ECD S2 Drills

Cutting length series* up to 3×d** 5×d 8×d 12×d

Overhang factor Kh 1 0.87 0.82 0.80

* tool overhang for MULTI-MASTER tools

** d - drill diameter

Example

A machining division technologist plans the process for manufacturing a part, which is produced

from annealed titanium Ti-6Al-4V. One of the machining operations is drilling a series of through-

holes in the part base, which have thickness 65 mm (2.56 in). The holes are 24 mm (0.945

in) in diameter, the diameter tolerance limits are ±0.065 mm (±0.0026 in). The technologist

decided to use an ISCAR drill for this operation. Recommend the drill and cutting data.

The hole depth/diameter ratio is 65/24≈2.7, so the drill cutting length series should be

3×d. The required accuracy for the diameter relates to ISO IT11 grade. SUMOCHAM

products are recommended as the first-choice drills. We can select the DCN 240-072-

32A-3D (24 mm Dia., 3×d cutting length series) as it provides IT10-IT9 hole accuracy (Table

29). This drill carries the head ICM 240 IC908 (IC908 – the preferred carbide grade).

Basic cutting speed Vo=38 m/min (125 sfm), Table 37. Machinability factor Km=1 (Table 9).

By assuming that the operational stability is normal (Ks=1), equation (9) gives starting speed Vc as below:

Vc=38×1×1=38 (m/min) or 125 sfm.

Spindle speed n=( 1000×38)⁄(π×24) =504 (rpm)

Basic feed fo=0.21 mm/rev (0.0082 IPR), Table 39.

Overhang ratio Kh=1 (Table 41).

Calculating feed f with the use of equation (10) gives the following result:

f=0.21×1=0.21 (mm/rev) or 0.0082 IPR.

Feed speed Vf=0.21×504=105.8 (mm/min) or 4.13 IPM.

Short and deep holes

Cutting length series

Commonly used terms “short” and “deep” holes do not have a strict definition.

It is widely accepted that drilling a hole of diameter d and (10…12)×d or higher in

depth relates to deep drilling, while holes having depth up to 5×d, are short.

In the terminology used by ISCAR, only a drilling depth of 12×d and higher is considered as deep.

Consequently, the holes with shallower depths are short. The drills intended for machining short holes

vary in their cutting length series: short (up to 3×d), long (4×d and 5×d) and extra-long (8×d and 12×d).

53