Page 13 - parting_4_productivity_3375101

P. 13

Parting with Extra Stability and Higher Productivity

TWISTED 2-SIDED D120 D52

D82

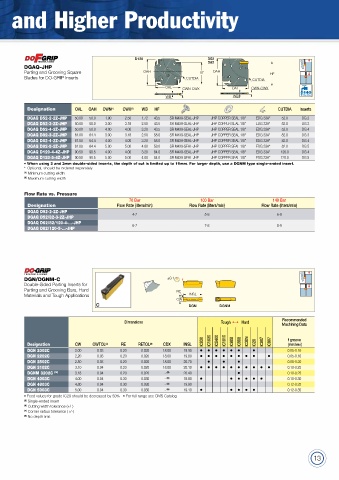

DGAQ-JHP

Parting and Grooving Square OAH HF OAH HF

Blades for DO-GRIP Inserts CUTDIA CUTDIA

OAL CWN-CWX OAL CWN-CWX

WB WB Bar Max

Designation OAL OAH CWN (1) CWX (2) WB HF CUTDIA Inserts

DGAQ D52-2-2Z-JHP 50.00 50.0 1.90 2.50 1.72 43.5 SR M4X9-SEAL-JHP JHP COPPER SEAL 1/8" EDG 33A* 52.0 DG 2

DGAQ D52-3-2Z-JHP 50.00 50.0 3.00 3.18 2.50 43.5 SR M4X9-SEAL-JHP JHP COPPER SEAL 1/8" EDG 33A* 52.0 DG 3

DGAQ D52-4-2Z-JHP 50.00 50.0 4.00 4.00 3.20 43.5 SR M4X9-SEAL-JHP JHP COPPER SEAL 1/8" EDG 33A* 52.0 DG 4

DGAQ D82-3-2Z-JHP 61.00 64.4 3.00 3.18 2.50 58.0 SR M4X9-SEAL-JHP JHP COPPER SEAL 1/8" EDG 33A* 82.0 DG 3

DGAQ D82-4-2Z-JHP 61.00 64.4 4.00 4.00 3.20 58.0 SR M4X9-SEAL-JHP JHP COPPER SEAL 1/8" EDG 33A* 82.0 DG 4

DGAQ D82-5-2Z-JHP 61.00 64.4 5.00 5.00 4.00 58.0 SR M4X9-SEAL-JHP JHP COPPER SEAL 1/8" EDG 33A* 82.0 DG 5

DGAQ D120-4-4Z-JHP 90.50 90.5 4.00 4.00 3.20 84.0 SR M4X9-SEAL-JHP JHP COPPER SEAL 1/8" EDG 33A* 120.0 DG 4

DGAQ D120-5-4Z-JHP 90.50 90.5 5.00 5.00 4.00 84.0 SR M4X9-SEAL-JHP JHP COPPER SEAL 1/8" EDG 33A* 120.0 DG 5

• When using 2 and 3mm double-sided inserts, the depth of cut is limited up to 19mm. For larger depth, use a DGNM type single-ended insert.

* Optional, should be ordered separately

(1) Minimum cutting width

(2) Maximum cutting width

Flow Rate vs. Pressure

70 Bar 100 Bar 140 Bar

Designation Flow Rate (liters/min) Flow Rate (liters/min) Flow Rate (liters/min)

DGAQ D52-2-2Z-JHP 4-7 5-8 6-9

DGAQ D52/82-3-2Z-JHP

DGAQ D52/82/120-4-...-JHP 6-7 7-8 8-9

DGAQ D82/120-5-...-JHP

DGN/DGNM-C ±0.1

Double-Sided Parting Inserts for

Parting and Grooving Bars, Hard RE

Materials and Tough Applications INSL

CW

DGN DGNM

Recommended

Dimensions Tough 1 Hard Machining Data

IC830 IC1030 IC5400 IC1010 IC808 IC908 IC30N IC807 IC907 f groove

Designation CW CWTOL (3) RE RETOL (4) CDX INSL IC20 (mm/rev)

DGN 2002C 2.00 0.03 0.20 0.020 18.00 19.90 • • • • • • • 0.05-0.16

DGN 2202C 2.20 0.03 0.20 0.020 18.00 19.80 • • • • • • • • • 0.05-0.16

DGN 2502C 2.50 0.03 0.20 0.020 18.00 20.70 • • • 0.08-0.20

DGN 3102C 3.10 0.04 0.20 0.020 18.00 20.10 • • • • • • • • • • 0.10-0.25

DGNM 3202C (2) 3.18 0.04 0.20 0.020 - (5) 20.40 • 0.10-0.25

DGN 4003C 4.00 0.04 0.30 0.030 - 18.80 • • • • • • 0.10-0.30

(5)

DGN 4803C 4.80 0.04 0.30 0.030 - 19.90 0.12-0.35

(5)

DGN 5003C 5.00 0.04 0.30 0.030 - 19.10 • • • • • 0.12-0.35

(5)

• Feed values for grade IC20 should be decreased by 50% • For full range see CMS Catalog

Single-ended insert

(2)

Cutting width tolerance (+/-)

(3)

Corner radius tolerance (+/-)

(4)

No depth limit

(5)

13