Page 36 - ISCAR_WORLD_2021

P. 36

Cutting Diamond

In manufacturing parts from composites, drilling

is widely regarded as the major cutting operation.

Improving capabilities of drilling tools has had a direct

impact on the effectiveness of machining composites

and composite stacks.

Most recently, ISCAR introduced a series of new

solid drills, in the diameter range of 3.3-12 mm

(.130-.500"), which are specially designed for

composites. The common feature of these tools is

the use of polycrystalline diamond (PCD) or diamond

coating to ensure high abrasion wear resistance. There

are several types of these new drills; one of them is

based on using a PCD nib as a central point of a drill,

and another type has a diamond wafer. Both drill types

offer a large area for multiple regrinding.

The third type of drills are solid carbide tools with a

diamond-coated cutting area. Their wavy cutting edge

facilitates reducing burr formation, specifically when

drilling carbon fiber reinforced plastics (CFRP) and

CFRP-Aluminum stacks.

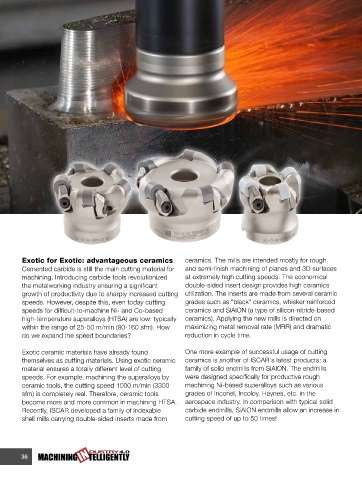

Exotic for Exotic: advantageous ceramics ceramics. The mills are intended mostly for rough

Cemented carbide is still the main cutting material for and semi-finish machining of planes and 3D surfaces

machining. Introducing carbide tools revolutionized at extremely high cutting speeds. The economical

the metalworking industry ensuring a significant double-sided insert design provides high ceramics

growth of productivity due to sharply increased cutting utilization. The inserts are made from several ceramic

speeds. However, despite this, even today cutting grades such as "black" ceramics, whisker reinforced

speeds for difficult-to-machine Ni- and Co-based ceramics and SiAlON (a type of silicon-nitride-based

high-temperature superalloys (HTSA) are low: typically ceramics). Applying the new mills is directed on

within the range of 25-50 m/min (80-160 sfm). How maximizing metal removal rate (MRR) and dramatic

do we expand the speed boundaries? reduction in cycle time.

Exotic ceramic materials have already found One more example of successful usage of cutting

themselves as cutting materials. Using exotic ceramic ceramics is another of ISCAR's latest products: a

material ensures a totally different level of cutting family of solid endmills from SiAlON. The endmills

speeds. For example, machining the superalloys by were designed specifically for productive rough

ceramic tools, the cutting speed 1000 m/min (3300 machining Ni-based superalloys such as various

sfm) is completely real. Therefore, ceramic tools grades of Inconel, Incoloy, Haynes, etc. in the

become more and more common in machining HTSA. aerospace industry. In comparison with typical solid

Recently, ISCAR developed a family of indexable carbide endmills, SiAlON endmills allow an increase in

shell mills carrying double-sided inserts made from cutting speed of up to 50 times!

DUSTRY 4.0

37

ISCAR

36 MACHINING IN TELLIGENTLY ISCAR 37