Page 78 - HOLE MAKING CATALOG p185-310

P. 78

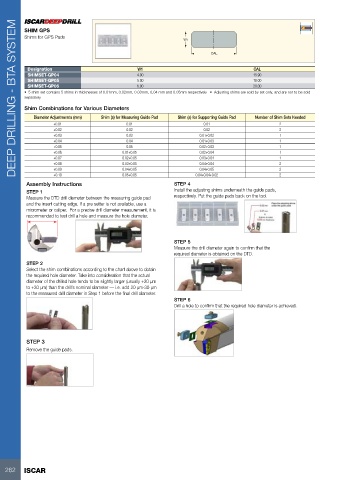

DEEP DRILLING - BTA SYSTEM SHIM GPS W1

Shims for GPS Pads OAL

Designation W1 OAL

SHIMSET-GP04 4.00 15.90

SHIMSET-GP05 5.00 18.00

6.00 20.00

SHIMSET-GP06

• 5 shim set contains 5 shims in thicknesses of 0.01mm, 0.02mm, 0.03mm, 0.04 mm and 0.05mm respectively • Adjusting shims are sold by set only, and are not to be sold

separately

Shim Combinations for Various Diameters

Diameter Adjustmemts (mm) Shim (s) for Measuring Guide Pad Shim (s) for Supporting Guide Pad Number of Shim Sets Needed

+0.01 0.01 0.01 2

+0.02 0.02 0.02 2

+0.03 0.03 0.01+0.02 1

+0.04 0.04 0.01+0.03 1

+0.05 0.05 0.02+0.03 1

+0.06 0.01+0.05 0.02+0.04 1

+0.07 0.02+0.05 0.03+0.04 1

+0.08 0.03+0.05 0.04+0.04 2

+0.09 0.04+0.05 0.04+0.05 2

+0.10 0.05+0.05 0.04+0.04+0.02 2

Assembly Instructions STEP 4

Install the adjusting shims underneath the guide pads,

STEP 1 respectively. Put the guide pads back on the tool.

Measure the DTD drill diameter between the measuring guide pad

and the insert cutting edge. If a pre setter is not available, use a

micrometer or caliper. For a precise drill diameter measurement, it is

recommended to test drill a hole and measure the hole diameter.

STEP 2 STEP 5

Select the shim combinations according to the chart above to obtain Measure the drill diameter again to confirm that the

the required hole diameter. Take into consideration that the actual required diameter is obtained on the DTD.

diameter of the drilled hole tends to be slightly larger (usually +20 μm

to +30 μm) than the drill’s nominal diameter — i.e. add 20 μm-30 μm STEP 6

to the measured drill diameter in Step 1 before the final drill diameter. Drill a hole to confirm that the required hole diameter is achieved.

STEP 3

Remove the guide pads.

262 ISCAR