Page 22 - MILLING CATALOG p319-550

P. 22

SLOTTING & SLITTING CUTTERS USER GUIDE

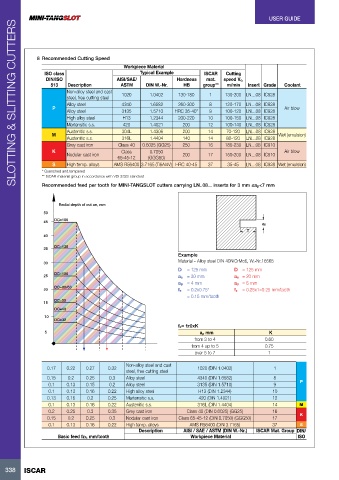

8 Recommended Cutting Speed

ISO class Workpiece Material ISCAR Cutting

DIN/ISO Typical Example mat. speed Vc,

group**

513 Description AISI/SAE/ Hardness m/min Insert Grade

ASTM DIN W.-Nr. HB 1 Coolant

Non-alloy steel and cast 1020 1.0402 130-180 8 130-200 LN….08 IC928

steel, free cutting steel 9

10

P Alloy steel 4340 1.6582 260-300 12 120-170 LN….08 IC928 Air blow

Alloy steel 3135 1.5710 HRC 35-40* 14 100-120 LN….08 IC928

14 100-150

High alloy steel H13 1.2344 200-220 16 100-140 LN….08 IC928

70-120

Martensitic s.s. 420 1.4021 200 17 80-120 LN….08 IC928

180-230

M Austenitic s.s. 304L 1.4306 200 37 LN….08 IC928 Wet (emulsion)

Austenitic s.s. 316L 1.4404 140 150-200 LN….08 IC928

Grey cast iron Class 40 0.6025 (GG25) 250 LN….08 IC910

K Nodular cast iron 200

Class 0.7050 LN….08 IC910 Air blow

65-45-12 (GGG50)

S High temp. alloys AMS R56400 3.7165 (Ti6Al4V) HRC 40-45 35-45 LN….08 IC928 Wet (emulsion)

* Quenched and tempered

** ISCAR material group in accordance with VDI 3323 standard

Recommended feed per tooth for MINI-TANGSLOT cutters carrying LN..08... inserts for 3 mm ≤ap<7 mm

Redial depth of cut ae, mm ap

50 T

45 DC=160

Example

40 Material - Alloy steel DIN 40NiCrMo6, W.-Nr.16565

35 DC=125

D = 125 mm D = 125 mm

30 ae = 30 mm ae = 20 mm

25 DC=100 ap = 4 mm ap = 6 mm

20 DC=80/63 fz = 0.2x0.75* fz = 0.25x1=0.25 mm/tooth

15 DC=50

= 0.15 mm/tooth

DC=40

10 DC=32 fz= fz0xK K

ap mm 0.60

5 0.75

from 3 to 4

from 4 up to 5 1

over 5 to 7

0.17 0.22 0.27 0.32 Non-alloy steel and cast 1020 (DIN 1.0402) 1

steel, free cutting steel

0.15 0.2 0.25 0.3 Alloy steel 4340 (DIN 1.6582) 8

0.2 Alloy steel 3135 (DIN 1.5710) 9P

0.1 0.13 0.15 0.22 High alloy steel H13 (DIN 1.2344)

0.25 Martensitic s.s. 420 (DIN 1.4021)

0.1 0.13 0.16 0.22 Austenitic s.s. 316L (DIN 1.4404) 10

0.35 Grey cast iron Class 40 (DIN 0.6025) (GG25)

0.13 0.16 0.2 0.3 Nodular cast iron Class 65-45-12 (DIN 0.7050) (GGG50) 12

0.22 High temp. alloys AMS R56400 (DIN 3.7165)

0.1 0.13 0.16 AISI / SAE / ASTM (DIN W.-Nr.) 14 M

Description Workpiece Material

0.2 0.25 0.3 16 K

17

0.15 0.2 0.25

0.1 0.13 0.16 37 S

ISCAR Mat. Group DIN/

Basic feed fz0, mm/tooth

ISO

338 ISCAR