Page 79 - TURNING CATALOG p255-458

P. 79

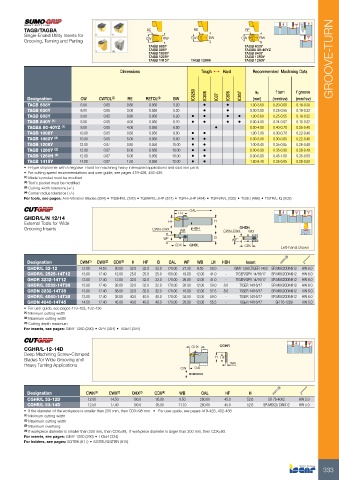

TAGB/TAGBA RE REIC8250 BW RE

Single-Ended Utility Inserts for CW BW CW IC808 CW BW

Grooving, Turning and Parting IC07

TAGB 608Y IC806 TAGB 630Y

TAGB 808Y TAGB 1260H IC807TAGBA 80-40YZ

TAGB 1008Y TAGB 840Y

TAGB 1208Y Tough 1 Hard GROOVE-TURNTAGB 1050Y

TAGB 1415Y TAGB 1260Y

Dimensions Recommended Machining Data

ap f turn f groove

Designation CW CWTOL(3) RE RETOL(4) BW (mm) (mm/rev) (mm/rev)

• • 1.00-3.60 0.20-0.60 0.18-0.30

TAGB 608Y 6.00 0.05 0.80 0.050 5.20 • • 0.00-3.00 0.25-0.55 0.18-0.32

TAGB 630Y 0.18-0.32

TAGB 808Y 6.00 0.05 3.00 0.050 5.20 0.18-0.32

TAGB 840Y (1) 8.00 0.05 0.80 0.050 6.20 • • • • 1.00-5.60 0.25-0.55 0.25-0.40

TAGBA 80-40YZ (1) 8.00 0.05 4.00 0.050 6.20 • • • • 0.00-4.00 0.24-0.67 0.22-0.40

TAGB 1008Y 8.00 0.05 4.00 0.050 6.00 • 0.00-4.00 0.40-0.70 0.22-0.40

TAGB 1050Y (2) 8.00 • • 0.26-0.48

10.00 0.05 0.80 0.050 8.00 • • 1.00-7.00 0.30-0.70 0.26-0.48

TAGB 1208Y 0.35-0.55

TAGB 1260Y (2) 10.00 0.05 5.00 0.050 0.00-5.00 0.30-0.85 0.26-0.50

TAGB 1260H (2) 0.80 0.050 10.00 • •

TAGB 1415Y 12.00 0.07 6.00 0.050 10.00 • • 1.00-8.40 0.35-0.85

12.00 0.07 6.00 0.050 10.00 • • 0.00-6.00 0.35-0.90

1.50 0.050 12.00 • •

12.00 0.07 0.00-6.00 0.45-1.00

14.00 0.07 1.80-8.40 0.35-0.85

• H-type chipformer with a negative T-land for machining heavy interrupted applications and cast iron parts

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Blade's pocket must be modified

(2) Tool's pocket must be modified

(3) Cutting width tolerance (+/-)

(4) Corner radius tolerance (+/-)

For tools, see pages: Anti-Vibration Blades (284) • TGBHR/L (330) • TGBHR/L-JHP (331) • TGFH-JHP (494) • TGFH/R/L (332) • TGSU (496) • TGTR/L-IQ (502)

GHDR/L/N 12/14 LH OAL

External Tools for Wide

Grooving Inserts HF H

GHDN

CWN-CWX WB HBH

CWN-CWX WB

WF GHDL B WF Left-hand shown

CDX

CDX

Designation CWN(1) CWX(2) CDX(3) H HF B OAL WF WB LH HBH Insert

GHDR/L 32-12 12.00 14.53 30.00 32.0 32.0 32.0 170.00 27.30 9.50 50.0 - GIMY 1260,TIGER 1453 SR M8X20DIN912 HW 6.0

GHDR/L 2525-14T12 13.00 17.40 12.00 25.0 25.0 25.0 150.00 19.00 12.00 41.0 - TIGER/GPV 14/16/17 SR M8X20DIN912 HW 6.0

13.00 17.40 12.00 32.0 32.0 32.0 170.00 26.00 12.00 41.0 - TIGER/GPV 14/16/17 SR M8X20DIN912 HW 6.0

GHDR 3232-14T12

GHDR/L 3232-14T38 13.00 17.40 38.00 32.0 32.0 32.0 170.00 26.00 12.00 59.0 8.0 TIGER 14/16/17 SR M8X20DIN912 HW 6.0

GHDN 3232-14T38 13.00 17.40 38.00 32.0 32.0 32.0 170.00 16.00 12.00 57.5 8.0 TIGER 14/16/17 SR M8X20DIN912 HW 6.0

GHDR/L 4040-14T38 13.00 17.40 38.00 40.0 40.0 40.0 170.00 34.00 12.00 59.0 - TIGER 14/16/17 SR M8X20DIN912 HW 6.0

GHDN 4040-14T45 14.50 17.40 45.00 40.0 40.0 40.0 170.00 20.00 12.00 55.5 - TIGER 14/16/17 HW 5.0

SR 76-1289

• For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Cutting depth maximum

For inserts, see pages: GIMY 1260 (290) • GPV (304) • TIGER (334)

CGHR/L-12-14D OHX CGHR

Deep Machining Screw-Clamped CW OAL

Blades for Wide Grooving and H HF

Heavy Turning Applications WB

Designation CWN(1) CWX(2) OHX(3) CDX(4) WB OAL HF H

52.6 SR 76-4002 HW 5.0

CGHR/L 53-12D 12.00 14.50 100.0 93.00 9.50 260.00 45.0 52.6 SR M6X25 DIN912 HW 5.0

CGHR/L 53-14D 12.50 17.40 100.0 93.00 11.10 260.00 45.0

• If the diameter of the workpiece is smaller than 200 mm, then CDX=98 mm • For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Maximum overhang

(4) If workpiece diameter is smaller than 200 mm, then CDX=98, if workpiece diameter is larger than 200 mm, then CDX=93.

For inserts, see pages: GIMY 1260 (290) • TIGER (334)

For holders, see pages: SGTBK (617) • SGTBU/SGTBN (616)

333