Page 41 - Iscar_Article_Brochure

P. 41

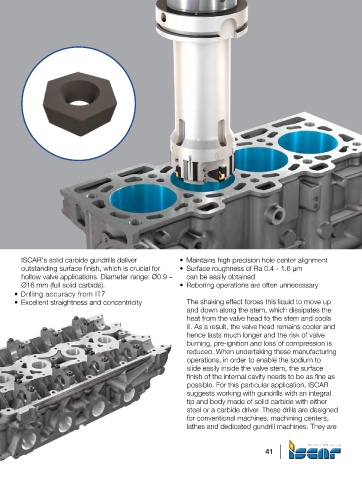

ISCAR's solid carbide gundrills deliver • Maintains high precision hole center alignment

outstanding surface finish, which is crucial for • Surface roughness of Ra 0.4 - 1.6 µm

hollow valve applications. Diameter range: Ø0.9 – can be easily obtained

Ø16 mm (full solid carbide). • Reboring operations are often unnecessary

• Drilling accuracy from IT7

• Excellent straightness and concentricity The shaking effect forces this liquid to move up

and down along the stem, which dissipates the

heat from the valve head to the stem and cools

it. As a result, the valve head remains cooler and

hence lasts much longer and the risk of valve

burning, pre-ignition and loss of compression is

reduced. When undertaking these manufacturing

operations, in order to enable the sodium to

slide easily inside the valve stem, the surface

finish of the internal cavity needs to be as fine as

possible. For this particular application, ISCAR

suggests working with gundrills with an integral

tip and body made of solid carbide with either

steel or a carbide driver. These drills are designed

for conventional machines, machining centers,

lathes and dedicated gundrill machines. They are

41