Page 145 - Threading_Handbook

P. 145

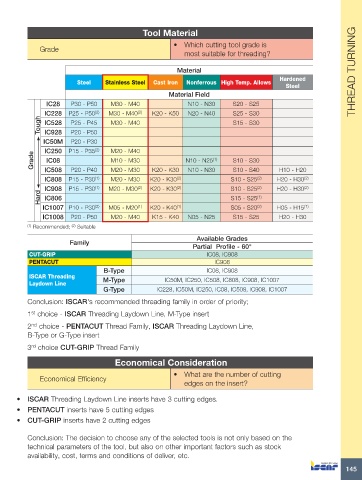

Tool Material

• Which cutting tool grade is

Grade

most suitable for threading?

Material THREAD TURNING

Hardened

Steel Stainless Steel Cast Iron Nonferrous High Temp. Allows

Steel

Material Field

IC28 P25 - P50 (2) M30 - M40 (2) K20 - K50 N10 - N30 S20 - S25

P30 - P50

M30 - M40

Tough IC228 P25 - P45 M30 - M40 S15 - S30

N20 - N40

S25 - S30

IC528

P20 - P50

IC928

IC50M P20 - P30

IC250 P15 - P35 (2) M20 - M40

Grade IC508 P20 - P40 M10 - M30 K20 - K30 N10 - N25 (1) S10 - S30 H10 - H20

IC08

M20 - M30

S10 - S40

N10 - N30

IC808 P15 - P30 (1) M20 - M30 K20 - K30 (2) S10 - S25 (2) H20 - H30 (2)

IC908 P15 - P30 (1) M20 - M30 (2) K20 - K30 (2) S10 - S25 (2) H20 - H30 (2)

Hard IC806 S15 - S25 (1)

IC1007 P10 - P30 (2) M05 - M20 (1) K20 - K40 (1) S05 - S20 (2) H05 - H15 (1)

IC1008 P20 - P50 M20 - M40 K15 - K40 N05 - N25 S15 - S25 H20 - H30

(1) Recommended; Suitable

(2)

Available Grades

Family

Partial Profile - 60°

CUT-GRIP IC08, IC908

PENTACUT IC908

B-Type IC08, IC908

ISCAR Threading IC50M, IC250, IC508, IC808, IC908, IC1007

Laydown Line M-Type

G-Type IC228, IC50M, IC250, IC08, IC508, IC908, IC1007

Conclusion: ISCAR's recommended threading family in order of priority;

1 choice - ISCAR Threading Laydown Line, M-Type insert

st

2 choice - PENTACUT Thread Family, ISCAR Threading Laydown Line,

nd

B-Type or G-Type insert

rd

3 choice CUT-GRIP Thread Family

Economical Consideration

• What are the number of cutting

Economical Efficiency

edges on the insert?

• ISCAR Threading Laydown Line inserts have 3 cutting edges.

• PENTACUT inserts have 5 cutting edges

• CUT-GRIP inserts have 2 cutting edges

Conclusion: The decision to choose any of the selected tools is not only based on the

technical parameters of the tool, but also on other important factors such as stock

availability, cost, terms and conditions of deliver, etc.

145