Page 236 - Threading_Handbook

P. 236

GRADES AND MATERIALS

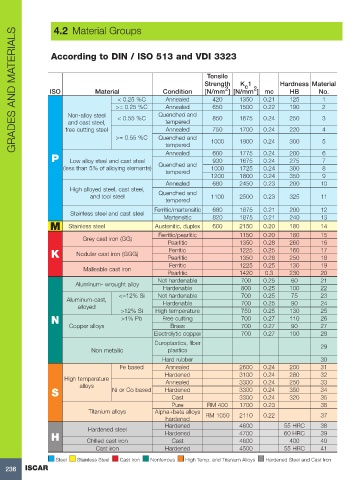

4.2 Material Groups

According to DIN / ISO 513 and VDI 3323

Tensile

Strength K 1 Hardness Material

c

2

2

ISO Material Condition [N/mm ] [N/mm ] mc HB No.

< 0.25 %C Annealed 420 1350 0.21 125 1

>= 0.25 %C Annealed 650 1500 0.22 190 2

Non-alloy steel < 0.55 %C Quenched and 850 1675 0.24 250 3

and cast steel, tempered

free cutting steel Annealed 750 1700 0.24 220 4

>= 0.55 %C Quenched and 1000 1900 0.24 300 5

tempered

P Low alloy steel and cast steel Annealed 600 1775 0.24 200 6

930

1675

275

0.24

7

(less than 5% of alloying elements) Quenched and 1000 1725 0.24 300 8

tempered

1200 1800 0.24 350 9

Annealed 680 2450 0.23 200 10

High alloyed steel, cast steel, Quenched and

and tool steel 1100 2500 0.23 325 11

tempered

Ferritic/martensitic 680 1875 0.21 200 12

Stainless steel and cast steel

Martensitic 820 1875 0.21 240 13

M Stainless steel Austenitic, duplex 600 2150 0.20 180 14

Ferritic/pearlitic 1150 0.20 180 15

Grey cast iron (GG)

Pearlitic 1350 0.28 260 16

Ferritic

K Nodular cast iron (GGG) Pearlitic 1225 0.25 160 17

250

0.28

1350

18

Ferritic 1225 0.25 130 19

Malleable cast iron

Pearlitic 1420 0.3 230 20

Not hardenable 700 0.25 60 21

Aluminum- wrought alloy

Hardenable 800 0.25 100 22

<=12% Si Not hardenable 700 0.25 75 23

Aluminum-cast, Hardenable 700 0.25 90 24

alloyed

>12% Si High temperature 750 0.25 130 25

N >1% Pb Free cutting 700 0.27 110 26

Copper alloys Brass 700 0.27 90 27

Electrolytic copper 700 0.27 100 28

Duroplastics, fiber

Non metallic plastics 29

Hard rubber 30

Fe based Annealed 2600 0.24 200 31

Hardened 3100 0.24 280 32

High temperature Annealed 3300 0.24 250 33

alloys

S Ni or Co based Hardened 3300 0.24 350 34

3300

0.24

35

Cast

320

Pure RM 400 1700 0.23 36

Titanium alloys Alpha+beta alloys RM 1050 2110 0.22 37

hardened

Hardened 4600 55 HRC 38

Hardened steel

H Chilled cast iron Hardened 4700 60 HRC 39

40

Cast

4600

400

Cast iron Hardened 4500 55 HRC 41

Steel Stainless Steel Cast Iron Nonferrous High Temp. and Titanium Alloys Hardened Steel and Cast Iron

236 ISCAR