Page 55 - Solid_Brochure_2021_INCH

P. 55

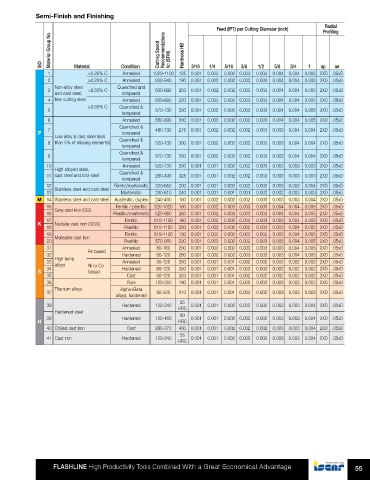

Semi-Finish and Finishing

Radial

Feed (IPT) per Cutting Diameter (inch) Profiling TEXT

Material Group No. Cutting Speed Recommendations Hardness HB

ISO Material Condition Vc (SFM) 3/16 1/4 5/16 3/8 1/2 5/8 3/4 1 ap ae

1 <0.25% C Annealed 1020-1100 125 0.001 0.002 0.002 0.003 0.003 0.004 0.004 0.005 2XD .05xD

2 ≥0.25% C Annealed 820-940 190 0.001 0.002 0.002 0.003 0.003 0.004 0.004 0.005 2XD .05xD

Non-alloy steel Quenched and

3 <0.55% C 650-890 250 0.001 0.002 0.002 0.003 0.003 0.004 0.004 0.005 2XD .05xD

and cast steel, tempered

4 free cutting steel Annealed 650-890 220 0.001 0.002 0.002 0.003 0.003 0.004 0.004 0.005 2XD .05xD

≥0.55% C Quenched &

5 570-730 300 0.001 0.002 0.002 0.003 0.003 0.004 0.004 0.005 2XD .05xD

tempered

6 Annealed 650-890 200 0.001 0.002 0.002 0.003 0.003 0.004 0.004 0.005 2XD .05xD

Quenched &

7 490-730 275 0.001 0.002 0.002 0.002 0.003 0.003 0.004 0.004 2XD .05xD

P tempered

Low alloy & cast steel (less

8 than 5% of alloying elements) Quenched & 520-730 300 0.001 0.002 0.002 0.002 0.003 0.003 0.004 0.004 2XD .05xD

tempered

Quenched &

9 570-730 350 0.001 0.002 0.002 0.002 0.003 0.003 0.004 0.004 2XD .05xD

tempered

10 Annealed 520-730 200 0.001 0.001 0.002 0.002 0.003 0.003 0.003 0.003 2XD .05xD

High alloyed steel,

11 cast steel and tool steel Quenched & 280-490 325 0.001 0.001 0.002 0.002 0.003 0.003 0.003 0.003 2XD .05xD

tempered

12 Stainless steel and cast steel Ferritic/martensitic 320-650 200 0.001 0.001 0.002 0.002 0.002 0.003 0.003 0.004 2XD .05xD

13 Martensitic 240-610 240 0.001 0.001 0.001 0.001 0.002 0.002 0.003 0.003 2XD .05xD

M 14 Stainless steel and cast steel Austenitic, duplex 240-490 180 0.001 0.002 0.002 0.002 0.003 0.003 0.003 0.004 2XD .05xD

15 Ferritic / pearlitic 320-1020 180 0.001 0.002 0.003 0.003 0.003 0.004 0.004 0.005 2XD .05xD

16 Grey cast iron (GG) Pearlitic/martensitic 520-980 260 0.001 0.002 0.003 0.003 0.003 0.004 0.004 0.005 2XD .05xD

17 Ferritic 610-1100 160 0.001 0.002 0.002 0.002 0.003 0.003 0.004 0.005 2XD .05xD

K Nodular cast iron (GGG)

18 Pearlitic 610-1100 250 0.001 0.002 0.002 0.002 0.003 0.003 0.004 0.005 2XD .05xD

19 Malleable cast iron Ferritic 610-1100 130 0.001 0.002 0.002 0.002 0.003 0.003 0.004 0.005 2XD .05xD

20 Pearlitic 570-980 230 0.001 0.002 0.002 0.002 0.003 0.003 0.004 0.005 2XD .05xD

31 Fe based Annealed 80-160 200 0.001 0.002 0.002 0.003 0.003 0.003 0.004 0.005 2XD .05xD

32 Hardened 80-120 280 0.001 0.002 0.002 0.003 0.003 0.003 0.004 0.005 2XD .05xD

33 High temp. Annealed 80-120 250 0.001 0.001 0.001 0.002 0.002 0.002 0.002 0.002 2XD .05xD

alloys

34 Ni or Co Hardened 80-120 350 0.001 0.001 0.001 0.002 0.002 0.002 0.002 0.002 2XD .05xD

S based

35 Cast 80-120 320 0.001 0.001 0.001 0.002 0.002 0.002 0.002 0.002 2XD .05xD

36 Pure 120-320 190 0.001 0.001 0.001 0.002 0.002 0.003 0.003 0.003 2XD .05xD

Titanium alloys Alpha+Beta

37 90-320 310 0.001 0.001 0.001 0.002 0.002 0.003 0.003 0.003 2XD .05xD

alloys, hardened

55

38 Hardened 120-240 HRC 0.001 0.001 0.002 0.002 0.002 0.003 0.003 0.004 2XD .05xD

Hardened steel

39 Hardened 120-160 60 0.001 0.001 0.002 0.002 0.002 0.003 0.003 0.004 2XD .05xD

H HRC

40 Chilled cast iron Cast 290-370 400 0.001 0.001 0.002 0.002 0.002 0.003 0.003 0.004 2XD .05xD

55

41 Cast iron Hardened 120-240 0.001 0.001 0.002 0.002 0.002 0.003 0.003 0.004 2XD .05xD

HRC

FLASHLINE High Productivity Tools Combined With a Great Economical Advantage 55