Page 62 - Solid_Brochure_2021_INCH

P. 62

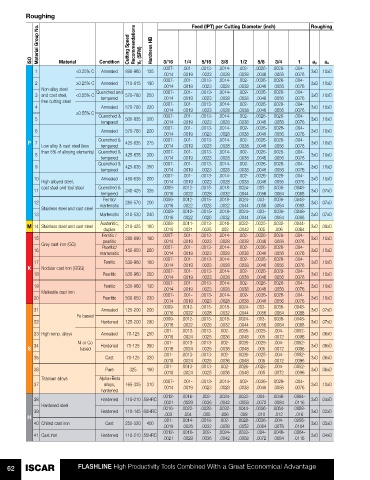

Roughing Feed (IPT) per Cutting Diameter (inch) Roughing

Material Group No. Cutting Speed Recommendations Hardness HB

ISO Material Condition Vc (SFM) 3/16 1/4 5/16 3/8 1/2 5/8 3/4 1 ap ae

.0007- .001- .0013- .0014- .002- .0026- .0028- .004-

1 <0.25% C Annealed 890-960 125 3xD .10xD

.0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076

.0007- .001- .0013- .0014- .002- .0026- .0028- .004-

2 ≥0.25% C Annealed 710-815 190 .0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076 3xD .10xD

Non-alloy steel

.001-

3 and cast steel, <0.55% C Quenched and 570-780 250 .0007- .0019 .0013- .0014- .002- .0026- .0028- .004- 3xD .10xD

.0028

.0023

.0014

.0076

tempered

.0056

.0038

.0046

free cutting steel

.001-

4 Annealed 570-780 220 .0007- .0019 .0013- .0014- .002- .0026- .0028- .004- 3xD .10xD

.0046

.0038

.0076

.0056

.0023

.0014

.0028

≥0.55% C Quenched & .0007- .001- .0013- .0014- .002- .0026- .0028- .004-

5 500-635 300 3xD .10xD

tempered .0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076

.0007- .001- .0013- .0014- .002- .0026- .0028- .004-

6 Annealed 570-780 200 3xD .10xD

.0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076

Quenched & .0007- .001- .0013- .0014- .002- .0026- .0028- .004-

P 7 425-635 275 3xD .10xD

Low alloy & cast steel (less tempered .0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076

than 5% of alloying elements) Quenched & .0007- .001- .0013- .0014- .002- .0026- .0028- .004-

8 425-635 300 3xD .10xD

tempered .0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076

Quenched & .0007- .001- .0013- .0014- .002- .0026- .0028- .004-

9 425-635 350 3xD .10xD

tempered .0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076

.0007- .001- .0013- .0014- .002- .0026- .0028- .004-

10 Annealed 450-635 200 3xD .10xD

High alloyed steel, .0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076

cast steel and tool steel Quenched & .0009- .0012- .0015- .0018- .0024- .003- .0036- .0048-

11 240-425 325 3xD .07xD

tempered .0016 .0022 .0028 .0032 .0044 .0056 .0064 .0088

Ferritic/ .0009- .0012- .0015- .0018- .0024- .003- .0036- .0048-

12 martensitic 280-570 200 .0016 .0022 .0028 .0032 .0044 .0056 .0064 .0088 3xD .07xD

Stainless steel and cast steel

13 Martensitic 210-530 240 .0009- .0012- .0015- .0018- .0024- .003- .0036- .0048- 3xD .07xD

.0016 .0022 .0028 .0032 .0044 .0056 .0064 .0088

Austenitic, .0008- .0011- .0013- .0016- .0022- .0025- .0032- .0044-

M 14 Stainless steel and cast steel 210-425 180 3xD .08xD

duplex .0015 .0021 .0025 .003 .0042 .005 .006 .0084

Ferritic / .0007- .001- .0013- .0014- .002- .0026- .0028- .004-

15 pearlitic 280-890 180 .0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076 3xD .10xD

Grey cast iron (GG)

16 Pearlitic/ 450-850 260 .0007- .001- .0013- .0014- .002- .0026- .0028- .004- 3xD .10xD

martensitic .0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076

.0007- .001- .0013- .0014- .002- .0026- .0028- .004-

17 Ferritic 530-960 160 3xD .10xD

.0023

.0014

.0028

.0046

.0056

K Nodular cast iron (GGG) .0007- .0019 .0013- .0014- .0038 .0026- .0028- .0076

.004-

.002-

.001-

18 Pearlitic 530-960 250 3xD .10xD

.0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076

.0007- .001- .0013- .0014- .002- .0026- .0028- .004-

19 Ferritic 530-960 130 .0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076 3xD .10xD

Malleable cast iron

20 Pearlitic 500-850 230 .0007- .001- .0013- .0014- .002- .0026- .0028- .004- 3xD .10xD

.0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076

.0009- .0012- .0015- .0018- .0024- .003- .0036- .0048-

31 Annealed 125-200 200 .0016 .0022 .0028 .0032 .0044 .0056 .0064 .0088 3xD .07xD

Fe based

32 Hardened 125-200 280 .0009- .0012- .0015- .0018- .0024- .003- .0036- .0048- 3xD .07xD

.0016 .0022 .0028 .0032 .0044 .0056 .0064 .0088

.001- .0013- .0013- .002- .0026- .0025- .004- .0052-

33 High temp. alloys Annealed 70-125 250 3xD .06xD

.0018 .0024 .0025 .0036 .0048 .005 .0072 .0096

Ni or Co .001- .0013- .0013- .002- .0026- .0025- .004- .0052-

34 Hardened 70-125 350 3xD .06xD

S based .0018 .0024 .0025 .0036 .0048 .005 .0072 .0096

.001- .0013- .0013- .002- .0026- .0025- .004- .0052-

35 Cast 70-125 320 3xD .06xD

.0018 .0024 .0025 .0036 .0048 .005 .0072 .0096

.001- .0013- .0013- .002- .0026- .0025- .004- .0052-

36 Pure 325 190 3xD .06xD

.0018 .0024 .0025 .0036 .0048 .005 .0072 .0096

Titanium alloys Alpha+Beta .0007- .001- .0013- .0014- .002- .0026- .0028- .004-

37 alloys, 165-325 310 .0014 .0019 .0023 .0028 .0038 .0046 .0056 .0076 3xD .10xD

hardened

.0012- .0016- .002- .0024- .0032- .004- .0048- .0064-

38 Hardened 110-210 55HRC .0021 .0029 .0036 .0042 .0058 .0072 .0084 .0116 3xD .04xD

Hardened steel

39 Hardened 110-145 60HRC .0016- .0022- .0028- .0032- .0044- .0056- .0064- .0088- 3xD .02xD

.016

.012

.010

.003

.005

.004

.006

.008

H .001- .0014- .0018- .002- .0028- .0036- .004- .0056-

40 Chilled cast iron Cast 250-320 400 3xD .05xD

.0019 .0026 .0032 .0038 .0052 .0064 .0076 .0104

.0012- .0016- .002- .0024- .0032- .004- .0048- .0064-

41 Cast iron Hardened 110-210 55HRC 3xD .04xD

.0021 .0029 .0036 .0042 .0058 .0072 .0084 .0116

62 ISCAR FLASHLINE High Productivity Tools Combined With a Great Economical Advantage