Page 75 - Solid_Brochure_2021_INCH

P. 75

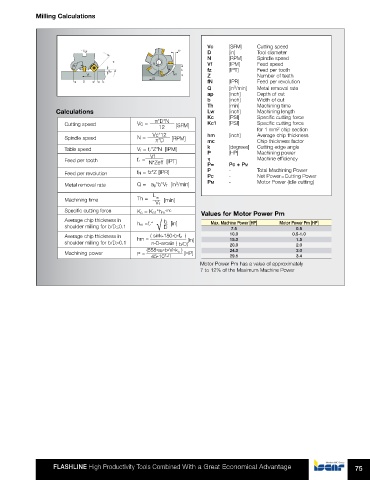

Milling Calculations

TEXT

Vc [SFM] Cutting speed

n fz D [in] Tool diameter

N [RPM] Spindle speed

κ

N n Vf [IPM] Feed speed

b fz [IPT] Feed per tooth

ap

Vf hm Z Number of teeth

Vf

D fz fN [IPR] Feed per revolution

3

Q [in /min] Metal removal rate

ap [inch] Depth of cut

b [inch] Width of cut

Th [min] Machining time

Calculations Lw [inch] Machining length

Kc [PSI] Specific cutting force

Cutting speed Vc = π*D*N [SFM] Kc1 [PSI] Specific cutting force

12 for 1 mm chip section

2

Spindle speed N = Vc*12 [RPM] hm [inch] Average chip thickness

π*D

mc

Chip thickness factor

Table speed Vf = fz*Z*N [IPM] k [degrees] Cutting edge angle

Vf P [HP] Machining power

Feed per tooth fz = N*Zeff [IPT] η Machine efficiency

P= Pc + Pm

Feed per revolution fN = fz*Z [IPR] P - - Total Machining Power

Pc

Net Power=Cutting Power

3

Metal removal rate Q = ap*b*Vf [in /min] Pm - Motor Power (idle cutting)

w

Machining time Th = L [min]

Vf

Specific cutting force Kc = Kc1*hm -mc Values for Motor Power Pm

√

Average chip thickness in hm ≈fz* [in] Max. Machine Power [HP] Motor Power Pm [HP]

b

shoulder milling for b/D≤0.1 D 7.5 0.5

Average chip thickness in hm = ( sink 180 b fz ) 10.0 0.5-1.0

* *

*

shoulder milling for b/D>0.1 π D arcsin ( b/D) [in] 15.0 1.5

* *

20.0

2.0

(558 ap b Vf k c ) 24.0 3.0

* * * *

Machining power P = 7 η [HP]

*

45 10 * 29.5 3.4

Motor Power Pm has a value of approximately

7 to 12% of the Maximum Machine Power

FLASHLINE High Productivity Tools Combined With a Great Economical Advantage 75