Page 129 - HOLE_MAKING_CATALOG_INCH_2022_P237-P372

P. 129

USER GUIDE

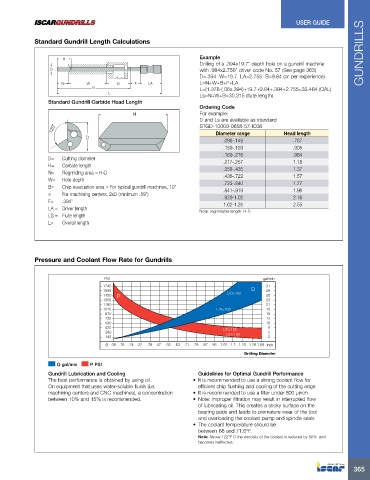

Standard Gundrill Length Calculations

H Example GUNDRILLS

Drilling of a .394x19.7” depth hole on a gundrill machine

D with .984x2.756” driver code No. 57 (See page 363)

D=.394 W=19.7 LA=2.755 B=9.84 (or per experience)

N W B F LA L=N+W+B+F+LA

Ls L=(1.378-(.06x.394)+19.7+9.84+.394+2.755=33.464 (OAL)

L

Ls=N+W+B=30.315 (flute length)

Standard Gundrill Carbide Head Length

Ordering Code

H For example:

D and Ls are available as standard

STGD-10000-0858-57-IC08

Diameter range Head length

D

.098-.149 .787

.150-.159 .905

.160-.216 .984

D= Cutting diameter .217-.257 1.18

H= Carbide length .258-.435 1.37

N= Regrinding area = H-D .436-.722 1.57

W= Hole depth .723-.840 1.77

B= Chip evacuation area = For typical gundrill machines, 10” .841-.919 1.96

= For machining centers, 2xD (minimum .59”) .920-1.02 2.16

F= .394” 1.02-1.26 2.55

LA = Driver length Note: regrindable length=H-D

LS = Flute length

L= Overall length

Pressure and Coolant Flow Rate for Gundrills

PSI gal/min

1740 Q 31

1595 29

1450 P L/D>100 26

1305 23

1160 21

1015 L/D<100 18

870 16

725 13

580 10

435 L/D>100 8

290 L/D<100 5

145 2

Ø .08 .16 .24 .32 .39 .47 .55 .63 .71 .79 .87 .95 1.02 1.1 1.18 1.26 1.58 inch

Drilling Diameter

Q gal/min P PSI

Gundrill Lubrication and Cooling Guidelines for Optimal Gundrill Performance

The best performance is obtained by using oil. • It is recommended to use a strong coolant flow for

On equipment that uses water-soluble fluids (i.e. efficient chip flushing and cooling of the cutting edge

machining centers and CNC machines), a concentration • It is recommended to use a filter under 800 μinch

between 10% and 15% is recommended. • Note: Improper filtration may result in interrupted flow

of lubricating oil. This creates a sticky surface on the

bearing pads and leads to premature wear of the tool

and overloading the coolant pump and spindle seals

• The coolant temperature should be

between 68 and 71.6°F.

Note: Above 122°F C the viscosity of the coolant is reduced by 50% and

becomes ineffective.

365