Page 51 - HOLE_MAKING_CATALOG_INCH_2022_P373-P446

P. 51

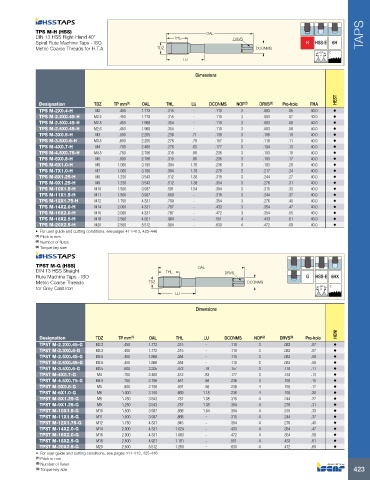

TPS M-H (HSS) OAL

DIN 13 HSS Right-Hand 40° THL DRVS TAPS

Spiral Flute Machine Taps - ISO H HSS-E 6H

Metric Coarse Threads for H.T.A. TDZ DCONMS

60˚ C

P

LU

Dimensions

HEST

Designation TDZ TP mm (1) OAL THL LU DCONMS NOF (2) DRVS (3) Pre-hole FHA

TPS M-2X0.4-H M2 .400 1.772 .315 - .110 3 .083 .06 40.0 •

TPS M-2.2X0.45-H M2.2 .450 1.772 .315 - .110 3 .083 .07 40.0 •

TPS M-2.5X0.45-H M2.5 .450 1.968 .354 - .110 3 .083 .08 40.0 •

TPS M-2.6X0.45-H M2.6 .450 1.968 .354 - .110 3 .083 .08 40.0 •

TPS M-3X0.5-H M3 .500 2.205 .236 .71 .138 3 .106 .10 40.0 •

TPS M-3.5X0.6-H M3.5 .600 2.205 .276 .79 .157 3 .118 .11 40.0 •

TPS M-4X0.7-H M4 .700 2.480 .276 .83 .177 3 .134 .13 40.0 •

TPS M-4.5X0.75-H M4.5 .750 2.756 .315 .98 .236 3 .193 .15 40.0 •

TPS M-5X0.8-H M5 .800 2.756 .315 .98 .236 3 .193 .17 40.0 •

TPS M-6X1.0-H M6 1.000 3.150 .394 1.18 .236 3 .193 .20 40.0 •

TPS M-7X1.0-H M7 1.000 3.150 .394 1.18 .276 3 .217 .24 40.0 •

TPS M-8X1.25-H M8 1.250 3.543 .512 1.38 .315 3 .244 .27 40.0 •

TPS M-9X1.25-H M9 1.250 3.543 .512 1.38 .354 3 .276 .31 40.0 •

TPS M-10X1.5-H M10 1.500 3.937 .591 1.54 .394 3 .315 .33 40.0 •

TPS M-11X1.5-H M11 1.500 3.937 .669 - .315 3 .244 .37 40.0 •

TPS M-12X1.75-H M12 1.750 4.331 .709 - .354 3 .276 .40 40.0 •

TPS M-14X2.0-H M14 2.000 4.331 .787 - .433 3 .354 .47 40.0 •

TPS M-16X2.0-H M16 2.000 4.331 .787 - .472 3 .354 .55 40.0 •

TPS M-18X2.5-H M18 2.500 4.921 .984 - .551 4 .433 .61 40.0 •

TPS M-20X2.5-H M20 2.500 5.512 .984 - .630 4 .472 .69 40.0 •

• For user guide and cutting conditions, see pages 411-413, 425-446

(1) Pitch in mm

(2) Number of flutes

(3) Torque key size

TPST M-G (HSS) OAL

DIN 13 HSS Straight THL DRVS

Flute Machine Taps - ISO G HSS-E 6HX

Metric Coarse Threads TDZ DCONMS

for Grey Cast Iron 60˚ P C

LU

Dimensions

HENI

Designation TDZ TP mm (1) OAL THL LU DCONMS NOF (2) DRVS (3) Pre-hole

TPST M-2.2X0.45-G M2.2 .450 1.772 .315 - .110 3 .083 .07 •

TPST M-2.3X0.4-G M2.3 .400 1.772 .315 - .110 3 .083 .07 •

TPST M-2.5X0.45-G M2.5 .450 1.968 .354 - .110 3 .083 .08 •

TPST M-2.6X0.45-G M2.6 .450 1.968 .354 - .110 3 .083 .08 •

TPST M-3.5X0.6-G M3.5 .600 2.205 .472 .79 .157 3 .118 .11 •

TPST M-4X0.7-G M4 .700 2.480 .512 .83 .177 3 .134 .13 •

TPST M-4.5X0.75-G M4.5 .750 2.756 .551 .98 .236 3 .193 .15 •

TPST M-5X0.8-G M5 .800 2.756 .591 .98 .236 4 .193 .17 •

TPST M-6X1.0-G M6 1.000 3.150 .669 1.18 .236 4 .193 .20 •

TPST M-8X1.25-G M8 1.250 3.543 .787 1.38 .315 4 .244 .27 •

TPST M-9X1.25-G M9 1.250 3.543 .787 1.38 .354 4 .276 .31 •

TPST M-10X1.5-G M10 1.500 3.937 .866 1.54 .394 4 .315 .33 •

TPST M-11X1.5-G M11 1.500 3.937 .866 - .315 4 .244 .37 •

TPST M-12X1.75-G M12 1.750 4.331 .945 - .354 4 .276 .40 •

TPST M-14X2.0-G M14 2.000 4.331 1.024 - .433 4 .354 .47 •

TPST M-16X2.0-G M16 2.000 4.331 1.063 - .472 4 .354 .55 •

TPST M-18X2.5-G M18 2.500 4.921 1.181 - .551 4 .433 .61 •

TPST M-20X2.5-G M20 2.500 5.512 1.260 - .630 4 .472 .69 •

• For user guide and cutting conditions, see pages 411-413, 425-446

(1) Pitch in mm

(2) Number of flutes

(3) Torque key size 423