Page 27 - ISCAR's solutions for Heavy Machining 2022

P. 27

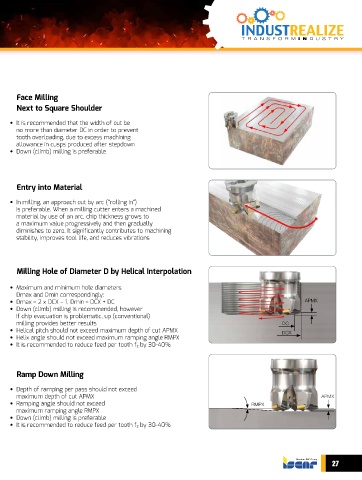

Face Milling

Next to Square Shoulder

• It is recommended that the width of cut be

no more than diameter DC in order to prevent

tooth overloading, due to excess machining

allowance in cusps produced after stepdown

• Down (climb) milling is preferable

Entry into Material

• In milling, an approach cut by arc (“rolling in”)

is preferable. When a milling cutter enters a machined

material by use of an arc, chip thickness grows to

a maximum value progressively and then gradually

diminishes to zero. It significantly contributes to machining

stability, improves tool life, and reduces vibrations

Milling Hole of Diameter D by Helical Interpolation

• Maximum and minimum hole diameters

Dmax and Dmin correspondingly:

• Dmax = 2 x DCX – 1, Dmin = DCX + DC APMX

• Down (climb) milling is recommended, however

if chip evacuation is problematic, up (conventional)

milling provides better results DC

• Helical pitch should not exceed maximum depth of cut APMX DCX

• Helix angle should not exceed maximum ramping angle RMPX

• It is recommended to reduce feed per tooth fz by 30-40%

Ramp Down Milling

• Depth of ramping per pass should not exceed

maximum depth of cut APMX APMX

• Ramping angle should not exceed RMPX

maximum ramping angle RMPX

• Down (climb) milling is preferable

• It is recommended to reduce feed per tooth fz by 30-40%

27