Page 53 - MILLING_CATALOG_INCH_2022_P229-P360

P. 53

Rd°

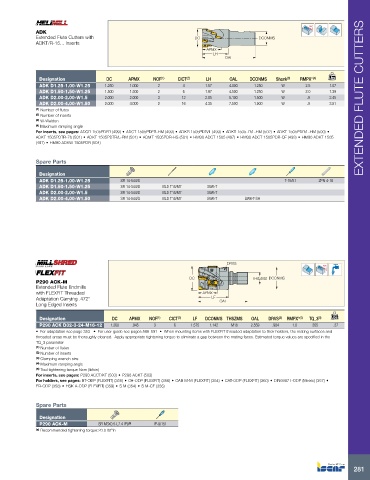

ADK

Extended Flute Cutters with DC DCONMS

ADKT/R-15... Inserts

APMX

LH

OAL

Designation DC APMX NOF (1) CICT (2) LH OAL DCONMS Shank (3) RMPX° (4) Lbs

ADK D1.25-1.00-W1.25 1.250 1.000 2 4 1.57 4.000 1.250 W 2.5 1.07

ADK D1.50-1.50-W1.25 1.500 1.500 2 6 1.97 4.500 1.250 W 2.0 1.39

ADK D2.00-2.00-W1.5 2.000 2.000 3 12 2.05 5.100 1.500 W .9 2.45 EXTENDED FLUTE CUTTERS

ADK D2.00-4.00-W1.50 2.000 4.000 2 16 4.35 7.500 1.500 W .9 3.51

(1) Number of flutes

(2) Number of inserts

(3) W-Weldon

(4) Maximum ramping angle

For inserts, see pages: ADCR 1505PDFR (499) • ADCT 1505PDFR-HM (499) • ADKR 1505PDR/L (499) • ADKT 1505..R/L-HM (502) • ADKT 1505PDR/L-HM (500) •

ADKT 1505PDTR-76 (501) • ADKT 1505PDTR/L-RM (501) • ADMT 1505PDR-HS (501) • HM90 ADCT 1505 (497) • HM90 ADCT 1505PDR-CF (498) • HM90 ADKT 1505

(497) • HM90 ADKW 1505PDR (504)

Spare Parts

Designation

ADK D1.25-1.00-W1.25 SR 14-544/S T-15/51 ZPN 4-18

ADK D1.50-1.50-W1.25 SR 14-544/S BLD T15/M7 SW6-T

ADK D2.00-2.00-W1.5 SR 14-544/S BLD T15/M7 SW6-T

ADK D2.00-4.00-W1.50 SR 14-544/S BLD T15/M7 SW6-T SW6-T-SH

DRVS Rd°

P290 ACK-M DC THSZMS DCONMS

Extended Flute Endmills

with FLEXFIT Threaded APMX

Adaptation Carrying .472" LF OAL

Long Edged Inserts

Designation DC APMX NOF (1) CICT (2) LF DCONMS THSZMS OAL DRVS (3) RMPX° (4) TQ_3 (5) Lbs

P290 ACK D32-3-24-M16-12 1.260 .945 3 6 1.575 1.142 M16 2.559 .984 1.0 355 .37

• For adaptation see page 353 • For user guide see pages 586-591 • When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and

threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the

TQ_3 parameter

(1) Number of flutes

(2) Number of inserts

(3) Clamping wrench size

(4) Maximum ramping angle

(5) Tool tightening torque Nxm (lbfxin)

For inserts, see pages: P290 ACCT/KT (503) • P290 ACKT (503)

For holders, see pages: BT-ODP (FLEXFIT) (356) • C#-ODP (FLEXFIT) (356) • CAB M-M (FLEXFIT) (354) • CAT-ODP (FLEXFIT) (360) • DIN69871-ODP (Metric) (357) •

ER-ODP (358) • HSK A-ODP (FLEXFIT) (359) • S M (354) • S M-CF (355)

Spare Parts

Designation

P290 ACK-M SR M3X0.5-L7.4 IP9 (a) IP-9/151

(a) Recommended tightening torque:20.0 lbf*in

281