Page 116 - MILLING_CATALOG_INCH_2022_P361-P592

P. 116

USER GUIDE

THREAD MILLING TOOLS

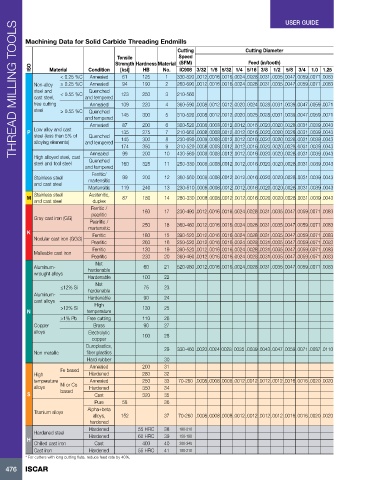

Machining Data for Solid Carbide Threading Endmills

Cutting Cutting Diameter

Tensile Speed

Strength Hardness Material (SFM) Feed (in/tooth)

ISO Material Condition [ksi] HB No. IC908 3/32 1/8 5/32 1/4 5/16 3/8 1/2 5/8 3/4 1.0 1.25

< 0.25 %C Annealed 61 125 1 330-820 .0012 .0016 .0016 .0024 .0028 .0031 .0035 .0047 .0059 .0071 .0083

Non-alloy ≥ 0.25 %C Annealed 94 190 2 260-690 .0012 .0016 .0016 .0024 .0028 .0031 .0035 .0047 .0059 .0071 .0083

steel and < 0.55 %C Quenched 123 250 3 210-560

cast steel, and tempered

free cutting Annealed 109 220 4 360-590 .0008 .0012 .0012 .0020 .0024 .0028 .0031 .0039 .0047 .0059 .0071

steel ≥ 0.55 %C Quenched

and tempered 145 300 5 310-520 .0008 .0012 .0012 .0020 .0025 .0028 .0031 .0039 .0047 .0059 .0071

Annealed 87 200 6 300-520 .0008 .0008 .0012 .0012 .0016 .0020 .0020 .0028 .0031 .0039 .0043

Low alloy and cast

P 135 275 7 210-660 .0008 .0008 .0012 .0012 .0016 .0020 .0020 .0028 .0031 .0039 .0043

steel (less than 5% of Quenched

alloying elements) and tempered 145 300 8 230-690 .0008 .0008 .0012 .0012 .0016 .0020 .0020 .0028 .0031 .0039 .0043

174 350 9 310-520 .0008 .0008 .0012 .0012 .0016 .0020 .0020 .0028 .0031 .0039 .0043

Annealed 99 200 10 430-560 .0008 .0008 .0012 .0012 .0016 .0020 .0020 .0028 .0031 .0039 .0043

High alloyed steel, cast

steel and tool steel Quenched 160 325 11 250-330 .0008 .0008 .0012 .0012 .0016 .0020 .0020 .0028 .0031 .0039 .0043

and tempered

Ferritic/

Stainless steel martensitic 99 200 12 360-560 .0008 .0008 .0012 .0012 .0016 .0020 .0020 .0028 .0031 .0039 .0043

and cast steel

Martensitic 119 240 13 230-510 .0008 .0008 .0012 .0012 .0016 .0020 .0020 .0028 .0031 .0039 .0043

Stainless steel Austenitic,

M 87 180 14 280-330 .0008 .0008 .0012 .0012 .0016 .0020 .0020 .0028 .0031 .0039 .0043

and cast steel duplex

Ferritic /

pearlitic 160 17 230-490 .0012 .0016 .0016 .0024 .0028 .0031 .0035 .0047 .0059 .0071 .0083

Gray cast iron (GG)

Pearlitic /

martensitic 250 18 360-460 .0012 .0016 .0016 .0024 .0028 .0031 .0035 .0047 .0059 .0071 .0083

K Ferritic 180 15 390-520 .0012 .0016 .0016 .0024 .0028 .0031 .0035 .0047 .0059 .0071 .0083

Nodular cast iron (GGG)

Pearlitic 260 16 250-520 .0012 .0016 .0016 .0024 .0028 .0031 .0035 .0047 .0059 .0071 .0083

Ferritic 130 19 390-520 .0012 .0016 .0016 .0024 .0028 .0031 .0035 .0047 .0059 .0071 .0083

Malleable cast iron

Pearlitic 230 20 360-460 .0012 .0016 .0016 .0024 .0028 .0031 .0035 .0047 .0059 .0071 .0083

Not

Aluminum- hardenable 60 21 520-980 .0012 .0016 .0016 .0024 .0028 .0031 .0035 .0047 .0059 .0071 .0083

wrought alloys

Hardenable 100 22

Not

≤12% Si hardenable 75 23

Aluminum- Hardenable 90 24

cast alloys

>12% Si High 130 25

N temperature

>1% Pb Free cutting 110 26

Copper Brass 90 27

alloys Electrolytic

copper 100 28

Duroplastics, 29 330-460 .0020 .0024 0028 0035 .0039 .0043 .0047 .0059 .0071 .0087 .0110

Non metallic fiber plastics

Hard rubber 30

Annealed 200 31

Fe based

High Hardened 280 32

temperature Annealed 250 33 70-260 .0008 .0008 .0008 .0012 .0012 .0012 .0012 .0016 .0016 .0020 .0020

alloys Ni or Co Hardened 350 34

S based Cast 320 35

Pure 58 36

Alpha+beta

Titanium alloys

alloys, 152 37 70-260 .0008 .0008 .0008 .0012 .0012 .0012 .0012 .0016 .0016 .0020 .0020

hardened

Hardened 55 HRC 38 180-210

Hardened steel

H Hardened 60 HRC 39 150-180

Chilled cast iron Cast 400 40 300-340

Cast iron Hardened 55 HRC 41 180-210

* For cutters with long cutting flute, reduce feed rate by 40%.

476 ISCAR