Page 52 - MILLING_CATALOG_INCH_2022_P93-P228

P. 52

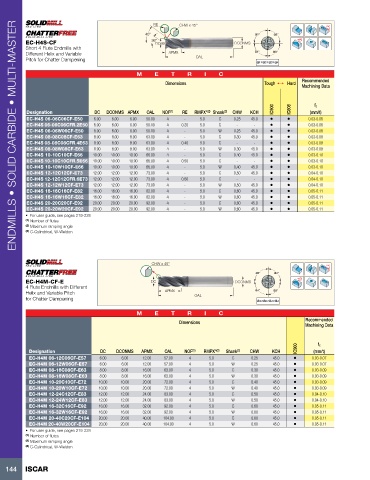

RE CHW x 45° Rd°

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

40° a1° a2°

EC-H4S-CF 36° DCe9 DCONMS

Short 4 Flute Endmills with

Different Helix and Variable APMX a4° a3°

Pitch for Chatter Dampening OAL

a1≠a2≠a3≠a4

M E T R I C

Recommended

Dimensions Tough 1 Hard

Machining Data

IC900 IC608 fz

Designation DC DCONMS APMX OAL NOF (1) RE RMPX° (2) Shank (3) CHW KCH (mm/t)

EC-H4S 06-06C06CF-E50 6.00 6.00 6.00 50.00 4 - 5.0 C 0.25 45.0 • • 0.03-0.08

EC-H4S 06-06C06CFR.2E50 6.00 6.00 6.00 50.00 4 0.20 5.0 C - - • • 0.03-0.08

EC-H4S 06-06W06CF-E50 6.00 6.00 6.00 50.00 4 - 5.0 W 0.25 45.0 • • 0.03-0.08

EC-H4S 08-08C08CF-E63 8.00 8.00 8.00 63.00 4 - 5.0 C 0.30 45.0 • • 0.03-0.08

EC-H4S 08-08C08CFR.4E63 8.00 8.00 8.00 63.00 4 0.40 5.0 C - - • • 0.03-0.08

EC-H4S 08-08W08CF-E63 8.00 8.00 8.00 63.00 4 - 5.0 W 0.30 45.0 • • 0.03-0.08

EC-H4S 10-10C10CF-E66 10.00 10.00 10.00 66.00 4 - 5.0 C 0.40 45.0 • • 0.03-0.10

EC-H4S 10-10C10CFR.5E66 10.00 10.00 10.00 66.00 4 0.50 5.0 C - - • • 0.03-0.10

EC-H4S 10-10W10CF-E66 10.00 10.00 10.00 66.00 4 - 5.0 W 0.40 45.0 • • 0.03-0.10

EC-H4S 12-12C12CF-E73 12.00 12.00 12.00 73.00 4 - 5.0 C 0.50 45.0 • • 0.04-0.10

EC-H4S 12-12C12CFR.6E73 12.00 12.00 12.00 73.00 4 0.60 5.0 C - - • • 0.04-0.10

EC-H4S 12-12W12CF-E73 12.00 12.00 12.00 73.00 4 - 5.0 W 0.50 45.0 • • 0.04-0.10

EC-H4S 16-16C16CF-E82 16.00 16.00 16.00 82.00 4 - 5.0 C 0.60 45.0 • • 0.05-0.11

EC-H4S 16-16W16CF-E82 16.00 16.00 16.00 82.00 4 - 5.0 W 0.60 45.0 • • 0.05-0.11

EC-H4S 20-20C20CF-E92 20.00 20.00 20.00 92.00 4 - 5.0 C 0.60 45.0 • • 0.05-0.11

EC-H4S 20-20W20CF-E92 20.00 20.00 20.00 92.00 4 - 5.0 W 0.60 45.0 • • 0.05-0.11

• For user guide, see pages 219-228

(1) Number of flutes

(2) Maximum ramping angle

(3) C-Cylindrical, W-Weldon

CHW x 45° Rd°

a1° a2°

EC-H4M-CF-E DC DCONMS

4 Flute Endmills with Different

Helix and Variable Pitch APMX OAL a4° a3°

for Chatter Dampening a1≠a2≠a3≠a4

M E T R I C

Recommended

Dimensions

Machining Data

IC900 fz

Designation DC DCONMS APMX OAL NOF (1) RMPX° (2) Shank (3) CHW KCH (mm/t)

EC-H4M 06-12C06CF-E57 6.00 6.00 12.00 57.00 4 5.0 C 0.25 45.0 • 0.03-0.07

EC-H4M 06-12W06CF-E57 6.00 6.00 12.00 57.00 4 5.0 W 0.25 45.0 • 0.03-0.07

EC-H4M 08-16C08CF-E63 8.00 8.00 16.00 63.00 4 5.0 C 0.30 45.0 • 0.03-0.09

EC-H4M 08-16W08CF-E63 8.00 8.00 16.00 63.00 4 5.0 W 0.30 45.0 • 0.03-0.09

EC-H4M 10-20C10CF-E72 10.00 10.00 20.00 72.00 4 5.0 C 0.40 45.0 • 0.03-0.09

EC-H4M 10-20W10CF-E72 10.00 10.00 20.00 72.00 4 5.0 W 0.40 45.0 • 0.03-0.09

EC-H4M 12-24C12CF-E83 12.00 12.00 24.00 83.00 4 5.0 C 0.50 45.0 • 0.04-0.10

EC-H4M 12-24W12CF-E83 12.00 12.00 24.00 83.00 4 5.0 W 0.50 45.0 • 0.04-0.10

EC-H4M 16-32C16CF-E92 16.00 16.00 32.00 92.00 4 5.0 C 0.60 45.0 • 0.05-0.11

EC-H4M 16-32W16CF-E92 16.00 16.00 32.00 92.00 4 5.0 W 0.60 45.0 • 0.05-0.11

EC-H4M 20-40C20CF-E104 20.00 20.00 40.00 104.00 4 5.0 C 0.60 45.0 • 0.05-0.11

EC-H4M 20-40W20CF-E104 20.00 20.00 40.00 104.00 4 5.0 W 0.60 45.0 • 0.05-0.11

• For user guide, see pages 219-228

(1) Number of flutes

(2) Maximum ramping angle

(3) C-Cylindrical, W-Weldon

144 ISCAR