Page 53 - Turning_catalog_INCH_2022_45_P691-914

P. 53

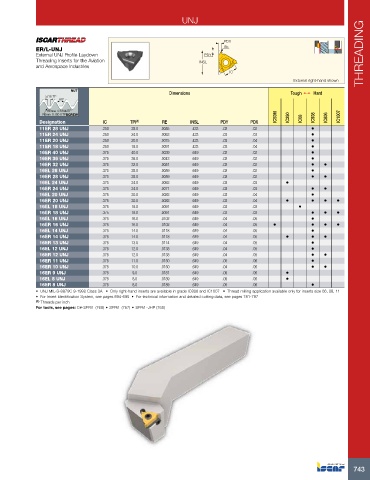

UNJ

PDX

ER/L-UNJ RE

External UNJ Profile Laydown PDY THREADING

Threading Inserts for the Aviation lNSL

and Aerospace Industries

IC

External right-hand shown

NUT

Dimensions Tough 1 Hard

5/16 TP

60°

REmax 0.18042TP

REmin 0.15011TPSCREW IC50M IC1007

Designation IC TPI (1) RE INSL PDY PDX IC250 IC08 IC908 IC806

11ER 28 UNJ .250 28.0 .0055 .433 .02 .02 •

11ER 24 UNJ .250 24.0 .0063 .433 .03 .03 •

11ER 20 UNJ .250 20.0 .0075 .433 .03 .04 •

11ER 18 UNJ .250 18.0 .0091 .433 .03 .04 •

16ER 40 UNJ .375 40.0 .0039 .649 .02 .02 •

16ER 36 UNJ .375 36.0 .0043 .649 .02 .02 •

16ER 32 UNJ .375 32.0 .0051 .649 .02 .02 • •

16EL 28 UNJ .375 28.0 .0059 .649 .02 .02 •

16ER 28 UNJ .375 28.0 .0059 .649 .02 .02 • •

16EL 24 UNJ .375 24.0 .0063 .649 .03 .03 •

16ER 24 UNJ .375 24.0 .0071 .649 .03 .03 • •

16EL 20 UNJ .375 20.0 .0083 .649 .03 .04 •

16ER 20 UNJ .375 20.0 .0083 .649 .03 .04 • • • •

16EL 18 UNJ .375 18.0 .0091 .649 .03 .03 •

16ER 18 UNJ .375 18.0 .0091 .649 .03 .03 • • •

16EL 16 UNJ .375 16.0 .0102 .649 .04 .05 •

16ER 16 UNJ .375 16.0 .0102 .649 .04 .05 • • • •

16EL 14 UNJ .375 14.0 .0118 .649 .04 .05 •

16ER 14 UNJ .375 14.0 .0118 .649 .04 .05 • • •

16ER 13 UNJ .375 13.0 .0114 .649 .04 .05 •

16EL 12 UNJ .375 12.0 .0138 .649 .04 .05 •

16ER 12 UNJ .375 12.0 .0138 .649 .04 .05 • •

16ER 11 UNJ .375 11.0 .0150 .649 .05 .06 •

16ER 10 UNJ .375 10.0 .0150 .649 .04 .06 • •

16ER 9 UNJ .375 9.0 .0181 .649 .05 .06 •

16EL 8 UNJ .375 8.0 .0189 .649 .05 .06 •

16ER 8 UNJ .375 8.0 .0189 .649 .05 .06 •

• UNJ MIL-S-8879C 9-1992 Class 3A • Only right-hand inserts are available in grade IC806 and IC1007 • Thread milling application available only for inserts size 06, 08, 11

• For Insert Identification System, see pages 694-695 • For technical information and detailed cutting data, see pages 781-797

(1) Threads per inch

For tools, see pages: C#-SER/L (768) • SER/L (767) • SER/L-JHP (768)

743