Page 59 - Aluminum_Machining_catalog_2023

P. 59

½ TAPS

Taps

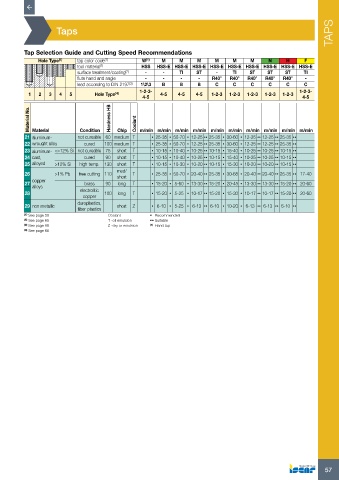

Tap Selection Guide and Cutting Speed Recommendations

Hole Type (4) tap color code (1) W (1) M M M M M M N H F

tool material (1) HSS HSS-E HSS-E HSS-E HSS-E HSS-E HSS-E HSS-E HSS-E HSS-E

surface treatment/coating (2) - - TI ST - TI ST ST ST TI

flute hand and angle - - - - R40° R40° R40° R40° R40° -

lead according to DIN 2197 (3) 1\2\3 B B B C C C C C C

1-2-3- 1-2-3-

1 2 3 4 5 Hole Type (4) 4-5 4-5 4-5 1-2-3 1-2-3 1-2-3 1-2-3 1-2-3

4-5 4-5

Material No. Hardness HB Coolant

Chip

Condition

Material

• 25-35 • 50-70 • 12-25 •• 25-35 • 30-60 • 12-25 •• 12-25 •• 25-35 ••

21 aluminum- not cureable 60 medium T m/min m/min m/min m/min m/min m/min m/min m/min m/min m/min

22 wrought alloy cured 100 medium T • 25-35 • 50-70 • 12-25 •• 25-35 • 30-60 • 12-25 •• 12-25 •• 25-35 ••

23 aluminum- <=12% Si not cureable 75 short T • 10-15 • 10-40 • 10-25 •• 10-15 • 15-40 • 10-25 •• 10-25 •• 10-15 ••

24 cast, cured 90 short T • 10-15 • 10-40 • 10-25 •• 10-15 • 15-40 • 10-25 •• 10-25 •• 10-15 ••

25 alloyed >12% Si high temp. 130 short T • 10-15 • 10-30 • 10-20 •• 10-15 • 15-30 • 10-20 •• 10-20 •• 10-15 ••

med/

26 >1% Pb free cutting 110 short T • 25-35 • 50-70 • 20-40 •• 25-35 • 30-65 • 20-40 •• 20-40 •• 25-35 •• 17-40

copper

27 brass 90 long T • 15-20 • 5-60 • 13-30 •• 15-20 • 20-45 • 13-30 •• 13-30 •• 15-20 •• 20-60

alloys

28 electrolitic 100 long T • 15-20 • 5-25 • 10-17 •• 15-20 • 15-30 • 10-17 •• 10-17 •• 15-20 •• 20-60

copper

duroplastics,

29 non metallic short Z • 6-10 • 5-25 • 6-13 •• 6-10 • 10-20 • 6-13 •• 6-13 •• 6-10 ••

fiber plastics

(1) See page 58 Coolant • Recommended

(2) See page 65 T -oil emulsion •• Suitable

(3) See page 66 Z -dry or emulsion (1) Hand tap

(4) See page 66

57