Page 300 - THREADING CATALOG

P. 300

USER GUIDE

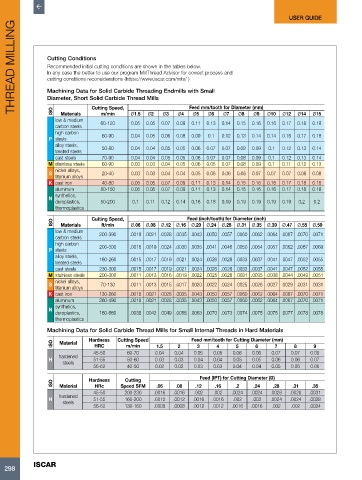

THREAD MILLING Cutting Conditions

Recommended initial cutting conditions are shown in the tables below.

In any case the better to use our program MillThread Advisor for correct process and

cutting conditions reconsiderations (https://www.iscar.com/mts/ )

Machining Data for Solid Carbide Threading Endmills with Small

Diameter, Short Solid Carbide Thread Mills

ISO

Ø12

Ø6

Ø9

Ø8

Ø7

Ø2

m/min

Materials

Ø3

Ø5

Ø4

low & medium Cutting Speed, Ø1.5 0.05 0.07 0.09 Feed mm/tooth for Diameter (mm) Ø10 0.17 Ø14 Ø15

0.13

0.16

0.05

0.18

60-120

0.11

0.15

0.18

0.14

0.16

carbon steels

high carbon

P steels 60-90 0.04 0.05 0.06 0.08 0.09 0.1 0.12 0.13 0.14 0.14 0.16 0.17 0.18

alloy steels, 50-80 0.04 0.04 0.05 0.05 0.06 0.07 0.07 0.08 0.09 0.1 0.12 0.13 0.14

treated steels

cast steels 70-90 0.04 0.04 0.05 0.05 0.06 0.07 0.07 0.08 0.09 0.1 0.12 0.13 0.14

M stainless steels 60-90 0.03 0.03 0.04 0.05 0.06 0.06 0.07 0.08 0.09 0.1 0.11 0.12 0.13

nickel alloys,

S 20-40 0.03 0.03 0.04 0.04 0.05 0.06 0.06 0.06 0.07 0.07 0.07 0.08 0.08

titanium alloys

K cast iron 40-80 0.05 0.05 0.07 0.09 0.11 0.13 0.14 0.15 0.16 0.16 0.17 0.18 0.18

aluminum 80-150 0.05 0.05 0.07 0.09 0.11 0.13 0.14 0.15 0.16 0.16 0.17 0.18 0.18

N synthetics,

duroplastics, 50-200 0.1 0.11 0.12 0.14 0.16 0.18 0.19 0.19 0.19 0.19 0.19 0.2 0.2

thermoplastics

Cutting Speed, Feed (inch/tooth) for Diameter (inch)

ISO Materials ft/min Ø.06 Ø.08 Ø.12 Ø.16 Ø.20 Ø.24 Ø.28 Ø.31 Ø.35 Ø.39 Ø.47 Ø.55 Ø.59

low & medium 200-390 .0018 .0021 .0028 .0035 .0043 .0050 .0057 .0060 .0062 .0064 .0067 .0070 .0071

carbon steels

high carbon

P steels 200-300 .0016 .0019 .0024 .0030 .0035 .0041 .0046 .0050 .0054 .0057 .0062 .0067 .0069

alloy steels, 160-260 .0015 .0017 .0019 .0021 .0024 .0026 .0028 .0033 .0037 .0041 .0047 .0052 .0055

treated steels

cast steels 230-300 .0015 .0017 .0019 .0021 .0024 .0026 .0028 .0033 .0037 .0041 .0047 .0052 .0055

M stainless steels 200-300 .0011 .0013 .0016 .0019 .0022 .0025 .0026 .0031 .0035 .0038 .0044 .0049 .0051

nickel alloys,

S 70-130 .0011 .0013 .0015 .0017 .0020 .0022 .0024 .0025 .0026 .0027 .0029 .0031 .0031

titanium alloys

K cast iron 130-260 .0018 .0021 .0028 .0035 .0043 .0050 .0057 .0060 .0062 .0064 .0067 .0070 .0071

aluminum 260-490 .0018 .0021 .0028 .0035 .0043 .0050 .0057 .0060 .0062 .0064 .0067 .0070 .0071

synthetics,

N

duroplastics, 160-660 .0038 .0042 .0049 .0056 .0063 .0070 .0073 .0074 .0075 .0075 .0077 .0078 .0078

thermoplastics

Machining Data for Solid Carbide Thread Mills for Small Internal Threads in Hard Materials

Hardness Cutting Speed Feed mm/tooth for Cutting Diameter (mm)

ISO Material HRC m/min 1.5 2 3 4 5 6 7 8 9

45-50 60-70 0.04 0.04 0.05 0.05 0.06 0.06 0.07 0.07 0.08

H hardened 51-55 50-60 0.03 0.03 0.04 0.04 0.05 0.05 0.06 0.06 0.07

steels

56-62 40-50 0.02 0.02 0.03 0.03 0.04 0.04 0.05 0.05 0.06

Hardness Cutting Feed (IPT) for Cutting Diameter (D)

ISO Material HRc Speed SFM .06 .08 .12 .16 .2 .24 .28 .31 .35

45-50 200-230 .0016 .0016 .002 .002 .0024 .0024 .0028 .0028 .0031

hardened

H 51-55 160-200 .0012 .0012 .0016 .0016 .002 .002 .0024 .0024 .0028

steels

56-62 130-160 .0008 .0008 .0012 .0012 .0016 .0016 .002 .002 .0024

ISCAR

298