Page 307 - THREADING CATALOG

P. 307

½

Thread Milling Tools and Inserts

SOLIDTHREAD THREAD MILLING

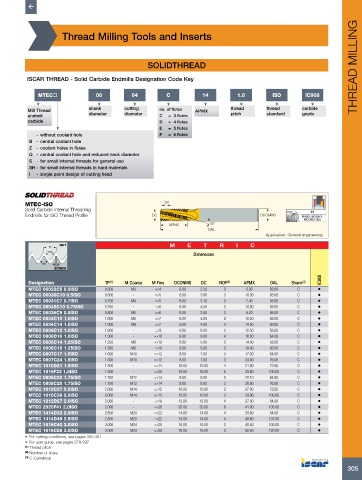

ISCAR THREAD - Solid Carbide Endmills Designation Code Key

MTEC 06 04 C 14 1.0 ISO IC908

Mill Thread shank cutting no. of flutes APMX thread thread carbide

endmill diameter diameter C = 3 flutes pitch standard grade

carbide D = 4 flutes

E = 5 flutes

- without coolant hole F = 6 flutes

B - central coolant hole

Z - coolant holes in flutes

Q - central coolant hole and reduced neck diameter

S - for small internal threads for general use

SH - for small internal threads in hard materials

I - single point design of cutting head

MTEC-ISO TP

Solid Carbide Internal Threading 6H

Endmills for ISO Thread Profile DC DCONMS DIN13, ISO 68-1,

ISO 965 (1&2)

APMX 15°

OAL

Application: General engineering

NUT M E T R I C

TP

TP/4

Dimensions

60˚

TP/8

SCREW

Designation TP (1) M Coarse M Fine DCONMS DC NOF (2) APMX OAL Shank (3) IC908

MTEC 06022C5 0.5ISO 0.500 M3 =>4 6.00 2.20 3 5.30 58.00 C •

MTEC 06038C10 0.5ISO 0.500 - =>5 6.00 3.80 3 10.30 58.00 C •

MTEC 06031C7 0.7ISO 0.700 M4 =>5 6.00 3.10 3 7.40 58.00 C •

MTEC 06045C10 0.75ISO 0.750 - =>6 6.00 4.50 3 10.00 58.00 C •

MTEC 06036C9 0.8ISO 0.800 M5 =>6 6.00 3.60 3 9.20 58.00 C •

MTEC 0604C10 1.0ISO 1.000 M6 =>7 6.00 4.00 3 10.50 58.00 C •

MTEC 0604C14 1.0ISO 1.000 M6 =>7 6.00 4.00 3 14.50 58.00 C •

MTEC 0606C12 1.0ISO 1.000 - =>9 6.00 6.00 3 12.50 58.00 C •

MTEC 0808D16 1.0ISO 1.000 - =>10 8.00 8.00 4 16.50 64.00 C •

MTEC 0605C14 1.25ISO 1.250 M8 =>10 6.00 5.00 3 14.40 58.00 C •

MTEC 0605C19 1.25ISO 1.250 M8 =>10 6.00 5.00 3 19.40 58.00 C •

MTEC 0807C17 1.5ISO 1.500 M10 =>12 8.00 7.00 3 17.30 64.00 C •

MTEC 0807C24 1.5ISO 1.500 M10 =>12 8.00 7.00 3 24.80 76.00 C •

MTEC 1010D21 1.5ISO 1.500 - =>14 10.00 10.00 4 21.80 73.00 C •

MTEC 1616F33 1.5ISO 1.500 - =>20 16.00 16.00 6 33.80 100.00 C •

MTEC 0808C20 1.75ISO 1.750 M12 =>14 8.00 8.00 3 20.10 64.00 C •

MTEC 0808C28 1.75ISO 1.750 M12 =>14 8.00 8.00 3 28.90 76.00 C •

MTEC 1010C27 2.0ISO 2.000 M14 =>15 10.00 10.00 3 27.00 73.00 C •

MTEC 1010C39 2.0ISO 2.000 M14 =>15 10.00 10.00 3 39.00 100.00 C •

MTEC 1212D27 2.0ISO 2.000 - =>18 12.00 12.00 4 27.00 84.00 C •

MTEC 2020F41 2.0ISO 2.000 - =>26 20.00 20.00 6 41.00 105.00 C •

MTEC 1414D33 2.5ISO 2.500 M20 =>22 14.00 14.00 4 33.80 84.00 C •

MTEC 1414D48 2.5ISO 2.500 M20 =>22 14.00 14.00 4 48.80 107.00 C •

MTEC 1616C40 3.0ISO 3.000 M24 =>25 16.00 16.00 3 40.50 100.00 C •

MTEC 1616C58 3.0ISO 3.000 M24 =>25 16.00 16.00 3 58.50 120.00 C •

• For cutting conditions, see pages 300-301

• For user guide, see pages 279-297

(1) Thread pitch

(2) Number of flutes

(3) C-Cylindrical

305