Page 372 - THREADING CATALOG

P. 372

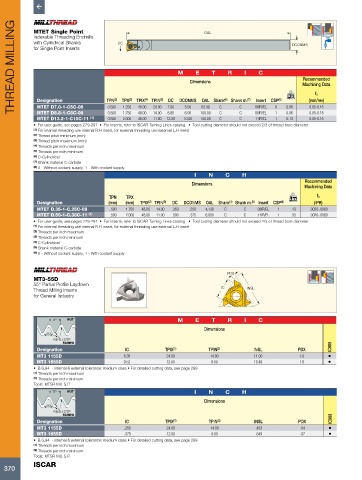

THREAD MILLING MTET Single Point DC M Dimensions T R I C DCONMS

OAL

Indexable Threading Endmills

with Cylindrical Shanks

for Single Point Inserts

E

Recommended

Machining Data

fz

kg

Designation

OAL Shank

DC

Insert

MTET D7.0-1-C5C-06

5.00

C

20.00

0.05-0.15

1.250

0.500

7.00

48.00

63.00

0

C

MTET D8.8-1-C6C-08

0.05-0.15

14.00

48.00

0.06

1

0.500

1.750

8.80

08IR/EL

6.00

0.500

11.00

0.13

48.00

1

2.000

11IR/EL

C

150.00

10.00

0.05-0.15

MTET D13.2-1-C10C-11 (1) TPN (2) TPX (3) TPIX (4) TPIN (5) 13.20 DCONMS 100.00 C C C (6) Shank m. (7) 06IR/EL CSP (8) 0.06 (mm/rev)

• For user guide, see pages 279-297 • For inserts, refer to ISCAR Turning Lines catalog • Tool cutting diameter should not exceed 2/3 of thread bore diameter

(1) For internal threading use internal R.H insert, for external threading use external L.H insert

(2) Thread pitch minimum (mm)

(3) Thread pitch maximum (mm)

(4) Threads per inch maximum

(5) Threads per inch minimum

(6) C-Cylindrical

(7) Shank material C-carbide

(8) 0 - Without coolant supply, 1 - With coolant supply

I N C H

Recommended

Dimensions

Machining Data

TPN TPX Lbs fz

Designation (mm) (mm) TPIX (2) TPIN (3) DC DCONMS OAL Shank (4) Shank m. (5) Insert CSP (6) (IPR)

MTET D.35-1-C.25C-08 .500 1.750 48.00 14.00 .350 .250 4.130 C C 08IR/EL 1 .13 .0020-.0060

MTET D.50-1-C.38C-11 (1) .500 2.000 48.00 11.00 .500 .375 6.000 C C 11IR/EL 1 .33 .0020-.0060

• For user guide, see pages 279-297 • For inserts, refer to ISCAR Turning Lines catalog • Tool cutting diameter should not exceed 2/3 of thread bore diameter

(1) For internal threading use internal R.H insert, for external threading use external L.H insert

(2) Threads per inch maximum

(3) Threads per inch minimum

(4) C-Cylindrical

(5) Shank material C-carbide

(6) 0 - Without coolant supply, 1 - With coolant supply

PDX

MT3-55D

55° Partial Profile Laydown

Thread Milling Inserts IC INSL

for General Industry

TP NUT M E T R I C

Dimensions

55°

RE=0.137TP

SCREW

Designation IC TPIX (1) TPIN (2) INSL PDX IC908

MT3 1155D 6.35 24.00 14.00 11.00 1.0 •

MT3 1655D 9.52 12.00 8.00 16.49 1.8 •

• B.S.84 - internal & external tolerance: medium class • For detailed cutting data, see page 299

(1) Threads per inch maximum

(2) Threads per inch minimum

Tools: MTSR M.I. S.P.

TP NUT I N C H

Dimensions

55°

RE=0.137TP

SCREW

Designation IC TPIX (1) TPIN (2) INSL PDX IC908

MT3 1155D .250 24.00 14.00 .433 .04 •

MT3 1655D .375 12.00 8.00 .649 .07 •

• B.S.84 - internal & external tolerance: medium class • For detailed cutting data, see page 299

(1) Threads per inch maximum

(2) Threads per inch minimum

Tools: MTSR M.I. S.P.

ISCAR

370