Page 380 - THREADING CATALOG

P. 380

USER GUIDE

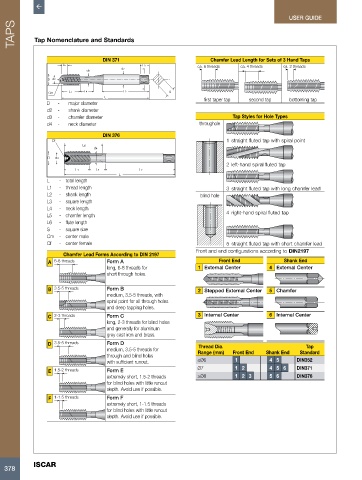

TAPS Tap Nomenclature and Standards

DIN 371 Chamfer Lead Length for Sets of 3 Hand Taps

L5 L3 ca. 6 threads ca. 4 threads ca. 2 threads

d2

d4

D d3

Cm L1 L4 L2 S

L first taper tap second tap bottoming tap

D - major diameter

d2 - shank diameter

d3 - chamfer diameter Tap Styles for Hole Types

d4 - neck diameter throughole

DIN 376

Cf 1 straight fluted tap with spiral point

L6

d4

D d3

2 left-hand spiral fluted tap

L1 L4 L2

L

L - total length

L1 - thread length 3 straight fluted tap with long chamfer lead

L2 - shank length blind hole

L3 - square length

L4 - neck length

L5 - chamfer length 4 right-hand spiral fluted tap

L6 - flute length

S - square size

Cm - center male

Cf - center female 5 straight fluted tap with short chamfer lead

Front and end configurations according to DIN2197

Chamfer Lead Forms According to DIN 2197

A 6-8 threads Form A Front End Shank End

long, 6-8 threads for 1 External Center 4 External Center

short through holes.

B 3.5-5 threads Form B 2 Stepped External Center 5 Chamfer

medium, 3.5-5 threads, with

spiral point for all through holes

and deep tapping holes.

C 2-3 threads Form C 3 Internal Center 6 Internal Center

long, 2-3 threads for blind holes

and generally for aluminum

grey cast iron and brass.

D 3.5-5 threads Form D Thread Dia. Tap

medium, 3.5-5 threads for Range (mm) Front End Shank End Standard

through and blind holes

with sufficient runout. ≤Ø6 1 4 5 DIN352

E 1.5-2 threads Form E Ø7 1 2 4 5 6 DIN371

extremely short, 1.5-2 threads ≥Ø8 1 2 3 5 6 DIN376

for blind holes with little runout

depth. Avoid use if possible.

F 1-1.5 threads Form F

extremely short, 1-1.5 threads

for blind holes with little runout

depth. Avoid use if possible.

ISCAR

378