Page 43 - THREADING CATALOG

P. 43

USER GUIDE

THREAD TURNING

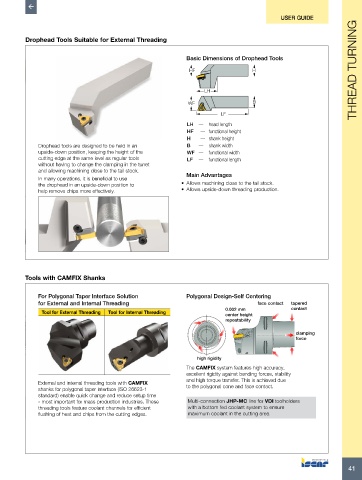

Drophead Tools Suitable for External Threading

Basic Dimensions of Drophead Tools

HF H

LH

WF B

LF

LH — head length

HF — functional height

H — shank height

Drophead tools are designed to be held in an B — shank width

upside-down position, keeping the height of the WF — functional width

cutting edge at the same level as regular tools LF — functional length

without having to change the clamping in the turret

and allowing machining close to the tail stock.

In many operations, it is beneficial to use Main Advantages

the drophead in an upside-down position to • Allows machining close to the tail stock.

help remove chips more effectively. • Allows upside-down threading production.

Tools with CAMFIX Shanks

For Polygonal Taper Interface Solution Polygonal Design-Self Centering

for External and Internal Threading face contact tapered

0.002 mm contact

Tool for External Threading Tool for Internal Threading center height

repeatability

clamping

force

high rigidity

The CAMFIX system features high accuracy,

excellent rigidity against bending forces, stability

External and internal threading tools with CAMFIX and high torque transfer. This is achieved due

shanks for polygonal taper interface (ISO 26623-1 to the polygonal cone and face contact.

standard) enable quick change and reduce setup time

- most important for mass production industries. These Multi-connection JHP-MC line for VDI toolholders

threading tools feature coolant channels for efficient with a bottom fed coolant system to ensure

flushing of heat and chips from the cutting edges. maximum coolant in the cutting area.

41