Page 63 - THREADING CATALOG

P. 63

USER GUIDE

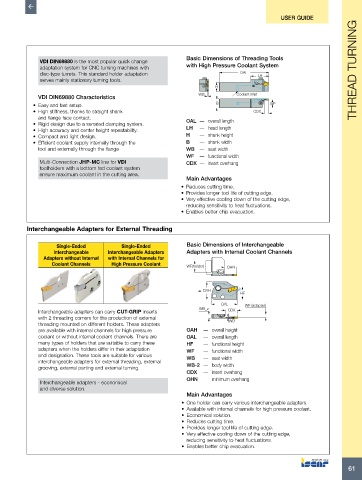

Basic Dimensions of Threading Tools

VDI DIN69880 is the most popular quick change

adaptation system for CNC turning machines with with High Pressure Coolant System THREAD TURNING

disc-type turrets. This standard holder adaptation OAL LH

serves mainly stationary turning tools.

H

VDI DIN69880 Characteristics WB Coolant inlet

• Easy and fast setup. B WF

• High stiffness, thanks to straight shank CDX

and flange face contact.

• Rigid design due to a serrated clamping system. OAL — overall length

• High accuracy and center height repeatability. LH — head length

• Compact and light design. H — shank height

• Efficient coolant supply internally through the B — shank width

tool and externally through the flange WB — seat width

WF — functional width

Multi-Connection JHP-MC line for VDI CDX — insert overhang

toolholders with a bottom fed coolant system

ensure maximum coolant in the cutting area.

Main Advantages

• Reduces cutting time.

• Provides longer tool life of cutting edge.

• Very effective cooling down of the cutting edge,

reducing sensitivity to heat fluctuations.

• Enables better chip evacuation.

Interchangeable Adapters for External Threading

Single-Ended Single-Ended Basic Dimensions of Interchangeable

Interchangeable Interchangeable Adapters Adapters with Internal Coolant Channels

Adapters without Internal with Internal Channels for

Coolant Channels High Pressure Coolant WF(holder) OHN

OAH

HF

OAL WF (adapter)

Interchangeable adapters can carry CUT-GRIP inserts WB_2 CDX

with 2 threading corners for the production of external WB

threading mounted on different holders. These adapters

are available with internal channels for high pressure OAH — overall height

coolant or without internal coolant channels. There are OAL — overall length

many types of holders that are suitable to carry these HF — functional height

adapters when the holders differ in their adaptation WF — functional width

and designation. These tools are suitable for various WB — seat width

interchangeable adapters for external threading, external

grooving, external parting and external turning. WB-2 — body width

CDX — insert overhang

OHN minimum overhang

Interchangeable adapters - economical

and diverse solution.

Main Advantages

• One holder can carry various interchangeable adapters.

• Available with internal channels for high pressure coolant.

• Economical solution.

• Reduces cutting time.

• Provides longer tool life of cutting edge.

• Very effective cooling down of the cutting edge,

reducing sensitivity to heat fluctuations.

• Enables better chip evacuation.

61