Page 167 - ISCAR FACE GROOVING LINES

P. 167

USER GUIDE

Coating Color*

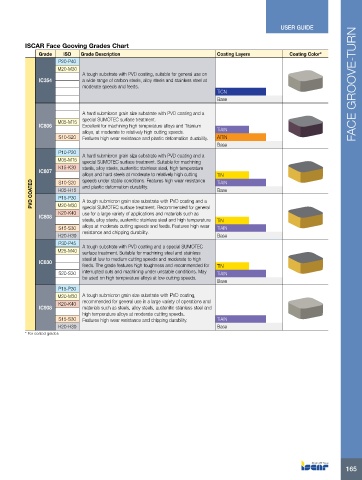

PVD COATEDISCAR Face Gooving Grades Chart

FACE GROOVE-TURNGrade ISO Grade DescriptionCoating Layers

P20-P40 TiCN

Base

M20-M30 A tough substrate with PVD coating, suitable for general use on

a wide range of carbon steels, alloy steels and stainless steel at

IC354 moderate speeds and feeds.

IC806 M05-M15 A hard submicron grain size substrate with PVD coating and a TiAlN

S10-S20 special SUMOTEC surface treatment. AlTiN

Excellent for machining high temperature alloys and Titanium Base

IC807 P10-P20 alloys, at moderate to relatively high cutting speeds.

M05-M15 Features high wear resistance and plastic deformation durability. TiN

K15-K30 TiAlN

A hard submicron grain size substrate with PVD coating and a Base

IC808 S10-S20 special SUMOTEC surface treatment. Suitable for machining

H05-H15 steels, alloy steels, austenitic stainless steel, high temperature TiN

P15-P30 alloys and hard steels at moderate to relatively high cutting TiAIN

M20-M30 speeds under stable conditions. Features high wear resistance Base

K20-K40 and plastic deformation durability.

TiN

S15-S30 A tough submicron grain size substrate with PVD coating and a TiAlN

H20-H30 special SUMOTEC surface treatment. Recommended for general Base

P30-P45 use for a large variety of applications and materials such as

M25-M40 steels, alloy steels, austenitic stainless steel and high temperature TiAlN

alloys at moderate cutting speeds and feeds. Features high wear Base

IC830 resistance and chipping durability.

S20-S30 A tough substrate with PVD coating and a special SUMOTEC

surface treatment. Suitable for machining steel and stainless

IC908 P15-P30 steel at low to medium cutting speeds and moderate to high

M20-M30 feeds. The grade features high toughness and recommended for

K20-K40 interrupted cuts and machining under unstable conditions. May

be used on high temperature alloys at low cutting speeds.

S15-S30

H20-H30 A tough submicron grain size substrate with PVD coating,

recommended for general use in a large variety of operations and

* For coated grades materials such as steels, alloy steels, austenitic stainless steel and

high temperature alloys at moderate cutting speeds.

Features high wear resistance and chipping durability.

165