Page 66 - HOLE MAKING CATALOG p311-382

P. 66

TAPS Regrinding USER GUIDE

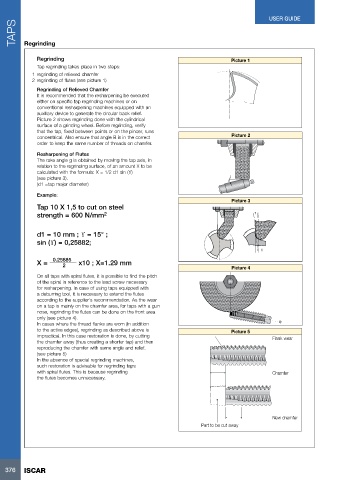

Regrinding Picture 1

Tap regrinding takes place in two steps:

1 regrinding of relieved chamfer Picture 2

2 regrinding of flutes (see picture 1)

β

Regrinding of Relieved Chamfer

It is recommended that the resharpening be executed Picture 3

either on specific tap regrinding machines or on

conventional resharpening machines equipped with an γ

auxiliary device to generate the circular back relief.

Picture 2 shows regrinding done with the cylindrical X

surface of a grinding wheel. Before regrinding, verify

that the tap, fixed between points or on the pincer, runs Picture 4

concentrical. Also ensure that angle B is in the correct

order to keep the same number of threads on chamfer.

Resharpening of Flutes

The rake angle g is obtained by moving the tap axis, in

relation to the regrinding surface, of an amount X to be

calculated with the formula: X = 1/2 d1 sin (ϒ)

(see picture 3).

(d1 =tap major diameter)

Example:

Tap 10 X 1,5 to cut on steel

strength = 600 N/mm2

d1 = 10 mm ; ϒ = 15° ;

sin (ϒ) = 0,25882;

X= 0.25885 x10 ; X=1.29 mm

2

On all taps with spiral flutes, it is possible to find the pitch Picture 5 ϕ

of the spiral in reference to the lead screw necessary Flank wear

for resharpening. In case of using taps equipped with

a deburring tool, it is necessary to extend the flutes Chamfer

according to the supplier’s recommendation. As the wear

on a tap is mainly on the chamfer area, for taps with a gun

nose, regrinding the flutes can be done on the front area

only (see picture 4).

In cases where the thread flanks are worn (in addition

to the active edges), regrinding as described above is

impractical. In this case restoration is done, by cutting

the chamfer away (thus creating a shorter tap) and then

reproducing the chamfer with same angle and relief.

(see picture 5)

In the absence of special regrinding machines,

such restoration is advisable for regrinding taps

with spiral flutes. This is because regrinding

the flutes becomes unnecessary.

New chamfer

Part to be cut away

376 ISCAR