Page 103 - HOLE MAKING CATALOG p383-544

P. 103

USER GUIDE ITS BORE

BHD Digital Fine Boring Head Metric/Inch Operating Instructions

123 Battery Replacement

When the batteries are low the display will show a warning

Fig. 3 (Nm) sign “batt” for a few seconds (FIG.4). It is recommended

2.0 to replace the batteries as soon as possible.

Locking Screw 2.5

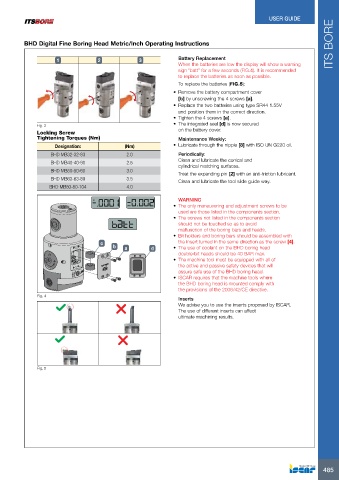

Tightening Torques (Nm) 3.0 To replace the batteries (FIG.5):

3.5

Designation: 4.0 • Remove the battery compartment cover

BHD MB32-32-83 [b] by unscrewing the 4 screws [a].

BHD MB40-40-90

BHD MB50-50-60 • Replace the two batteries using type SR44 1.55V

BHD MB63-63-89 and position them in the correct direction.

BHD MB80-80-104

• Tighten the 4 screws [a].

c ba d • The integrated seal [d] is now secured

Fig. 4 on the battery cover.

Maintenance Weekly:

• Lubricate through the nipple [8] with ISO UN G220 oil.

Periodically:

Clean and lubricate the conical and

cylindrical matching surfaces.

Treat the expanding pin [2] with an anti-friction lubricant.

Clean and lubricate the tool slide guide way.

WARNING

• The only maneuvering and adjustment screws to be

used are those listed in the components section.

• The screws not listed in the components section

should not be touched so as to avoid

malfunction of the boring bars and heads.

• Bit holders and boring bars should be assembled with

the insert turned in the same direction as the screw [4].

• The use of coolant on the BHD boring head

double-bit heads should be 40 BAR max.

• The machine tool must be equipped with all of

the active and passive safety devices that will

assure safe use of the BHD boring head.

• ISCAR requires that the machine tools where

the BHD boring head is mounted comply with

the provisions of the 2006/42/CE directive.

Inserts

We advise you to use the inserts proposed by ISCAR.

The use of different inserts can affect

ultimate machining results.

Fig. 5

485