Page 94 - HOLE MAKING CATALOG p383-544

P. 94

ITS BORE USER GUIDE

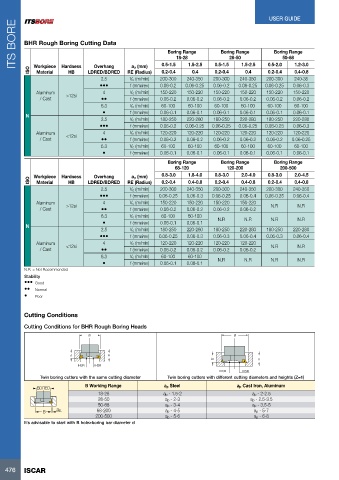

ISOBHR Rough Boring Cutting Data

Boring Range Boring Range Boring Range

18-28 28-50 50-68

Workpiece Hardness Overhang ap (mm) 0.5-1.5 1.5-2.5 0.5-1.5 1.5-2.5 0.5-2.0 1.2-3.0

Material HB LDRED/BDRED RE (Radius)

>12si Vc (m/min) 0.2-0.4 0.4 0.2-0.4 0.4 0.2-0.4 0.4-0.8

Aluminum 2.5

/ Cast <12si f (mm/rev) 200-300 240-350 200-300 240-350 200-300 240-35

••• Vc (m/min)

N f (mm/rev) 0.06-0.2 0.06-0.25 0.06-0.2 0.06-0.25 0.06-0.25 0.06-0.3

4 Vc (m/min)

Aluminum f (mm/rev) 150-220 150-220 150-220 150-220 150-220 150-220

/ Cast •• Vc (m/min)

f (mm/rev) 0.06-0.2 0.06-0.2 0.06-0.2 0.06-0.2 0.06-0.2 0.06-0.2

6.3 Vc (m/min)

f (mm/rev) 60-100 60-100 60-100 60-100 60-100 60-100

• Vc (m/min)

f (mm/rev) 0.06-0.1 0.06-0.1 0.06-0.1 0.06-0.1 0.06-0.1 0.06-0.1

2.5

ap (mm) 180-250 220-280 180-250 220-280 180-250 220-280

••• RE (Radius)

Vc (m/min) 0.06-0.2 0.06-0.25 0.06-0.25 0.06-0.25 0.06-0.25 0.06-0.3

4

f (mm/rev) 120-220 120-220 120-220 120-220 120-220 120-220

•• Vc (m/min)

f (mm/rev) 0.06-0.2 0.06-0.2 0.06-0.2 0.06-0.2 0.06-0.2 0.06-0.25

6.3 Vc (m/min)

f (mm/rev) 60-100 60-100 60-100 60-100 60-100 60-100

• Vc (m/min)

f (mm/rev) 0.06-0.1 0.06-0.1 0.06-0.1 0.06-0.1 0.06-0.1 0.06-0.1

Vc (m/min)

f (mm/rev) Boring Range Boring Range Boring Range

Vc (m/min) 68-120 120-200 200-500

f (mm/rev)

ISO Workpiece Hardness Overhang 0.8-3.0 1.8-4.0 0.8-3.0 2.0-4.0 0.8-3.0 2.0-4.5

LDRED/BDRED

Material HB 0.2-0.4 0.4-0.8 0.2-0.4 0.4-0.8 0.2-0.4 0.4-0.8

2.5

200-300 240-350 200-300 240-350 200-300 240-350

•••

0.06-0.25 0.06-0.3 0.06-0.25 0.06-0.4 0.06-0.25 0.06-0.4

4

Aluminum >12si 150-220 150-220 150-220 150-220 N.R N.R

/ Cast ••

0.06-0.2 0.06-0.2 0.06-0.2 0.06-0.2

6.3

60-100 60-100 N.R N.R N.R N.R

•

N 0.06-0.1 0.06-0.1 180-250 220-280

2.5 0.06-0.3 0.06-0.4

180-250 220-280 180-250 220-280

••• 0.06-0.3 0.06-0.4 N.R N.R

0.06-0.25 0.06-0.3 120-220 120-220

4 0.06-0.2 0.06-0.2

Aluminum <12si 120-220 120-220

/ Cast ••

0.06-0.2 0.06-0.2

6.3

60-100 60-100 N.R N.R N.R N.R

•

0.06-0.1 0.06-0.1

N.R. = Not Recommended

Stability

••• Good

•• Normal

• Poor

Cutting Conditions Ø

Cutting Conditions for BHR Rough Boring Heads

Ø

A A A1 A

IHSR IHSR

IHCR IHSR

Twin boring cutters with the same cutting diameter Twin boring cutters with different cutting diameters and heights (Z=1)

BDRED B Working Range ap Steel ap Cast Iron, Aluminum

B ap 18-28 ap - 1.5-2 ap - 2-2.5

28-50 ap - 2-3 ap - 2.5-3.5

50-68 ap - 3-4 ap - 3.5-5

68-200 ap - 4-5 ap - 5-7

ap - 5-6 ap - 6-8

200-500

It’s advisable to start with B hole≥boring bar diameter d

476 ISCAR