Page 37 - MILLING CATALOG p001-094

P. 37

Rd° ENDMILLS • SOLID CARBIDE • MULTI-MASTER

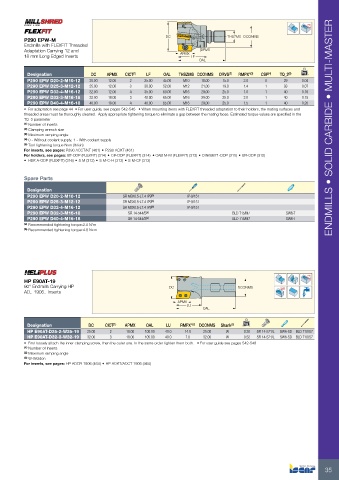

P290 EPW-M DC THSZMS DCONMS

Endmills with FLEXFIT Threaded

Adaptation Carrying 12 and APMX LF DRVS

18 mm Long Edged Inserts OAL

Designation DC APMX CICT(1) LF OAL THSZMS DCONMS DRVS(2) RMPX°(3) CSP(4) TQ_3(5) kg

P290 EPW D20-2-M10-12 20.00 12.00 2 25.00 45.00 M10 18.00 15.0 2.0 0 29 0.04

P290 EPW D25-3-M12-12 25.00 12.00 3 30.00 52.00 M12 21.00 19.0 1.4 1 33 0.07

P290 EPW D32-4-M16-12 32.00 12.00 4 35.00 60.00 M16 29.00 25.0 1.0 1 40 0.16

P290 EPW D32-3-M16-18 32.00 18.00 3 40.00 65.00 M16 29.00 25.0 2.0 1 40 0.15

P290 EPW D40-4-M16-18 40.00 18.00 4 40.00 65.00 M16 29.00 25.0 1.5 1 40 0.20

• For adaptation see page 44 • For user guide, see pages 542-548 • When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and

threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the

TQ_3 parameter

(1) Number of inserts

(2) Clamping wrench size

(3) Maximum ramping angle

(4) 0 - Without coolant supply, 1 - With coolant supply

(5) Tool tightening torque Nxm (lbfxin)

For inserts, see pages: P290 ACCT/KT (461) • P290 ACKT (461)

For holders, see pages: BT-ODP (FLEXFIT) (314) • C#-ODP (FLEXFIT) (314) • CAB M-M (FLEXFIT) (312) • DIN69871-ODP (315) • ER-ODP (315)

• HSK A-ODP (FLEXFIT) (316) • S M (312) • S M-C-H (312) • S M-CF (313)

Spare Parts SR M3X0.5-L7.4 IP9(b) IP-9/151

SR M3X0.5-L7.4 IP9(b) IP-9/151

Designation SR M3X0.5-L7.4 IP9(b) IP-9/151

P290 EPW D20-2-M10-12

P290 EPW D25-3-M12-12 SR 14-544/S(a) BLD T15/M7 SW6-T

P290 EPW D32-4-M16-12 SR 14-544/S(a) BLD T15/M7 SW6-T

P290 EPW D32-3-M16-18

P290 EPW D40-4-M16-18

(a) Recommended tightening torque:2.0 N*m

(b) Recommended tightening torque:4.8 Nxm

Rd°

HP E90AT-19 DC DCONMS

90° Endmills Carrying HP

AD.. 1906.. Inserts

APMX OAL

LU

Designation DC CICT(1) APMX OAL LU RMPX°(2) DCONMS Shank(3) kg

HP E90AT-D25-2-W25-19 25.00 2 18.00 100.00 40.0 14.0 25.00 W 0.30 SR 14-571/L SW6-SD BLD T10/S7

SW6-SD BLD T10/S7

HP E90AT-D32-3-W32-19 32.00 3 18.00 105.00 40.0 7.0 32.00 W 0.52 SR 14-571/L

• First loosely attach the inner clamping screw, then the outer one. In the same order tighten them both. • For user guide see pages 542-548

(1) Number of inserts

(2) Maximum ramping angle

(3) W-Weldon

For inserts, see pages: HP ADCR 1906 (464) • HP ADKT/ADCT 1906 (464)

35