Page 100 - MILLING CATALOG p319-550

P. 100

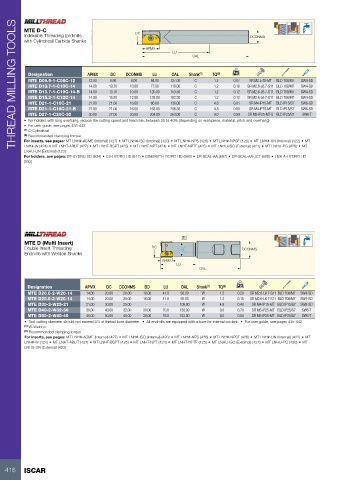

THREAD MILLING TOOLS MTE D-C DC DCONMS

Indexable Threading Endmills APMX

with Cylindrical Carbide Shanks

LU

OAL

Designation APMX DC DCONMS LU OAL Shank(1) TQ(2) kg

MTE D09.9-1-C08C-12 12.00 9.90 8.00 94.00 127.00 C 1.2 0.07 SR M2.5-T8-MT BLD T08/M7 SW4-SD

MTE D13.7-1-C10C-14 14.00 13.70 10.00 77.00 110.00 C 1.2 0.10 SR M2.6-L6.7-S11 BLD T08/M7 SW4-SD

MTE D13.7-1-C10C-14-B 14.00 13.70 10.00 120.00 153.50 C 1.2 0.12 SR M2.6-L6.7-S11 BLD T08/M7 SW4-SD

C 1.2 0.12 SR M2.6-L6.7-S11 BLD T08/M7 SW4-SD

MTE D15.2-1-C12C-14 14.00 15.20 12.00 139.00 182.30 C 4.8 0.01 SR M4-IP15-MT BLD IP15/S7 SW6-SD

C 4.8 0.60 SR M4-IP15-MT BLD IP15/S7 SW6-SD

MTE D21-1-C16C-21 21.00 21.00 16.00 86.60 130.00 C 9.0 0.99 SR M5-IP25-MT-S BLD IP25/S7 SW6-T

MTE D21-1-C16C-21-B 21.00 21.00 16.00 163.00 206.30

MTE D27-1-C20C-30 30.00 27.00 20.00 204.00 263.00

• For holders with long overhang, reduce the cutting speed and feed rate, between 20 to 40% (depending on workpiece, material, pitch and overhang)

• For user guide, see pages 435-442

(1) C-Cylindrical

(2) Recommended clamping torque

For inserts, see pages: MT LNH#-ACME (Internal) (427) • MT LNH#-ISO (Internal) (420) • MT LNH#-NPS (426) • MT LNH#-NPSF (426) • MT LNH#-UN (Internal) (422) • MT

LNH#-W (424) • MT LNHT-ABUT (427) • MT LNHT-BSPT (425) • MT LNHT-NPT (424) • MT LNHT-NPTF (425) • MT LNHU-ISO (External) (421) • MT LNHU-PG (428) • MT

LNHU-UN (External) (423)

For holders, see pages: BT-HYDRO HD (634) • C#-HYDRO HD (617) • DIN69871-HYDRO HD (569) • ER-SEAL-AA (687) • ER-SEAL-AA-JET (688) • HSK A-HYDRO HD

(592)

MTE D (Multi Insert) BD DCONMS

Double Insert Threading DC

Endmills with Weldon Shanks

APMX

LU

OAL

Designation APMX DC DCONMS BD LU OAL Shank(1) TQ(2) kg

MTE D20.0-2-W20-14 14.00 20.00 20.00 16.00 41.0 93.00 W 1.2 0.20 SR M2.6-L6.7-S11 BLD T08/M7 SW4-SD

MTE D20.0-3-W20-14 14.00 20.00 20.00 16.00 41.0 93.00 W 1.2 0.15 SR M2.6-L6.7-S11 BLD T08/M7 SW4-SD

21.00 30.00 25.00 W 4.8 0.40 SR M4-IP15-MT BLD IP15/S7 SW6-SD

MTE D30-2-W25-21 - - 108.00

MTE D40-2-W32-30 30.00 40.00 32.00 30.00 70.0 130.00 W 9.0 0.70 SR M5-IP25-MT BLD IP25/S7 SW6-T

MTE D50-2-W40-40 40.00 50.00 40.00 38.00 78.0 153.00 W 9.0 0.80 SR M5-IP25-MT BLD IP25/S7 SW6-T

• Tool cutting diameter should not exceed 2/3 of thread bore diameter • All endmills are equipped with a bore for internal coolant • For user guide, see pages 435-442

(1) W-Weldon

(2) Recommended clamping torque

For inserts, see pages: MT LNH#-ACME (Internal) (427) • MT LNH#-ISO (Internal) (420) • MT LNH#-NPS (426) • MT LNH#-NPSF (426) • MT LNH#-UN (Internal) (422) • MT

LNH#-W (424) • MT LNHT-ABUT (427) • MT LNHT-BSPT (425) • MT LNHT-NPT (424) • MT LNHT-NPTF (425) • MT LNHU-ISO (External) (421) • MT LNHU-PG (428) • MT

LNHU-UN (External) (423)

416 ISCAR