Page 121 - MILLING CATALOG p319-550

P. 121

USER GUIDE THREAD MILLING TOOLS

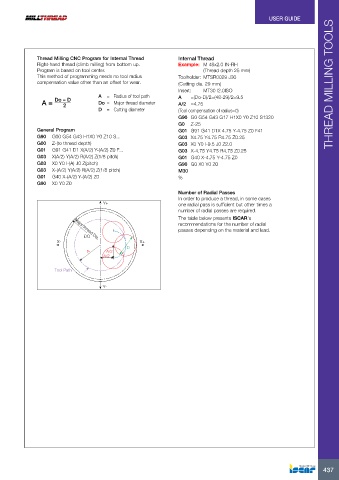

Thread Milling CNC Program for Internal Thread Internal Thread

Right-hand thread (climb milling) from bottom up. Example: M 48x2.0 IN-RH

Program is based on tool center.

This method of programming needs no tool radius (Thread depth 25 mm)

compensation value other than an offset for wear.

Toolholder: MTSR0029 J30

(Cutting dia. 29 mm)

A = Radius of tool path Insert: MT30 I2.0ISO

Do = Major thread diameter

A = Do – D D = Cutting diameter A =(Do-D)/2=(48-29)/2=9.5

2

A/2 =4.75

(Tool compensation of radius=0)

G90 G0 G54 G43 G17 H1X0 Y0 Z10 S1320

General Program G0 Z-25

G90 G00 G54 G43 H1X0 Y0 Z10 S...

G00 Z-(to thread depth) G01 G91 G41 D1X 4.75 Y-4.75 Z0 F41

G01 G91 G41 D1 X(A/2) Y-(A/2) Z0 F...

G03 X(A/2) Y(A/2) R(A/2) Z(1/8 pitch) G03 X4.75 Y4.75 R4.75 Z0.25

G03 X0 Y0 I-(A) J0 Z(pitch)

G03 X-(A/2) Y(A/2) R(A/2) Z(1/8 pitch) G03 X0 Y0 I-9.5 J0 Z2.0

G01 G40 X-(A/2) Y-(A/2) Z0

G90 X0 Y0 Z0 G03 X-4.75 Y4.75 R4.75 Z0.25

G01 G40 X-4.75 Y-4.75 Z0

G90 G0 X0 Y0 Z0

M30

%

Y+ Number of Radial Passes

In order to produce a thread, in some cases

Major thread one radial pass is sufficient but other times a

DO number of radial passes are required.

Dia.

The table below presents ISCAR's

recommendations for the number of radial

passes depending on the material and lead.

X- X+

D

A A/2

A/2

Tool Path

Y-

437