Page 122 - TURNING CATALOG p121-254

P. 122

ISOTURN INSERTS USER GUIDE

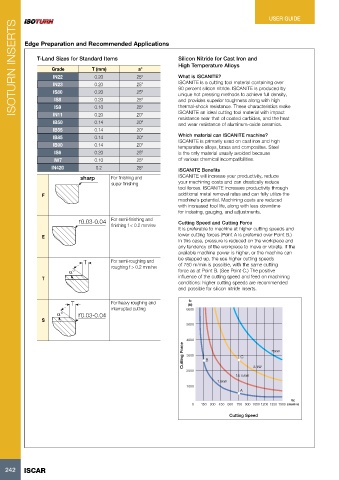

Edge Preparation and Recommended Applications

T-Land Sizes for Standard Items Silicon Nitride for Cast Iron and

High Temperature Alloys

Grade T (mm) a°

0.20 25° What is ISCANITE?

IN22 0.20 25° ISCANITE is a cutting tool material containing over

IN23 0.20 25° 90 percent silicon nitride. ISCANITE is produced by

IS80 0.20 25° unique hot pressing methods to achieve full density,

IS8 0.10 25° and provides superior toughness along with high

IS9 0.20 20° thermal-shock resistance. These characteristics make

IN11 0.14 20° ISCANITE an ideal cutting tool material with impact

IB50 0.14 20° resistance near that of coated carbides, and the heat

IB55 0.14 20° and wear resistance of aluminum-oxide ceramics.

IB85 0.14 20°

IB90 0.20 25° Which material can ISCANITE machine?

IS6 0.10 25° ISCANITE is primarily used on cast iron and high

IW7 0.2 25° temperature alloys, brass and composites. Steel

IN420 is the only material usually avoided because

of various chemical incompatibilities.

sharp For finishing and

super finishing ISCANITE Benefits

ISCANITE will increase your productivity, reduce

F your machining costs and can drastically reduce

tool forces. ISCANITE increases productivity through

r0.03-0.04 For semi-finishing and additional metal removal rates and can fully utilize the

finishing f < 0.2 mm/rev machine’s potential. Machining costs are reduced

with increased tool life, along with less downtime

E for indexing, gauging, and adjustments.

T For semi-roughing and Cutting Speed and Cutting Force

It is preferable to machine at higher cutting speeds and

roughing f > 0.2 mm/rev lower cutting forces (Point A is preferred over Point B.)

In this case, pressure is reduced on the workpiece and

α° any tendency of the workpiece to move or vibrate. If the

available machine power is higher, or the machine can

T be stepped up, the use higher cutting speeds

of 750 m/min is possible, with the same cutting

T For heavy roughing and force as at Point B. (See Point C.) The positive

influence of the cutting speed and feed on machining

interrupted cutting conditions: higher cutting speeds are recommended

and possible for silicon nitride inserts.

α° r0.03-0.04

fc

S (N)

6000

5000

4000

Cutting Force 3000 75kW

2000

1000 BC

37kW

18.75kW

7.5kW

A

Vc

0 150 300 450 600 750 900 1050 1200 1350 1500 (m/min)

Cutting Speed

242 ISCAR