Page 28 - TURNING CATALOG p255-458

P. 28

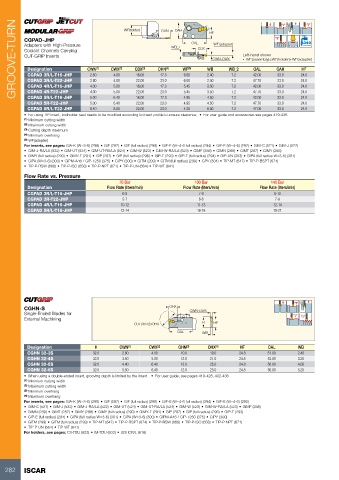

GROOVE-TURN WF(holder) OHN OAH HF

WB_2

CGPAD-JHP OAL WF (adapter) Bar Max

Adapters with High-Pressure CDX

Coolant Channels Carrying Left-hand shown

CUT-GRIP Inserts WB CWN-CWX • WF(assembly)=WF(holder)+WF(adapter)

Designation CWN(1) CWX(2) CDX(3) OHN(4) WF(5) WB WB_2 OAL OAH HF

CGPAD 3R/L-T16-JHP 2.80 4.00 16.00 17.3 6.00 2.40 7.2 42.00 33.0 24.0

CGPAD 3R/L-T22-JHP 2.80 4.00 22.00 23.0 6.00 2.40 7.2 47.70 33.0 24.0

CGPAD 4R/L-T16-JHP 4.00 5.00 16.00 17.3 5.45 3.50 7.2 42.00 33.0 24.0

CGPAD 4R-T22-JHP 4.00 5.00 22.00 23.0 5.45 3.50 7.2 47.70 33.0 24.0

CGPAD 5R/L-T16-JHP 5.00 6.40 16.00 17.3 4.95 4.50 7.2 42.00 33.0 24.0

CGPAD 5R-T22-JHP 5.00 6.40 22.00 23.0 4.95 4.50 7.2 47.70 33.0 24.0

CGPAD 8R/L-T22-JHP 6.40 8.00 22.00 23.0 4.20 6.00 7.2 47.00 33.0 24.0

• For using TIP insert, toolholder seat needs to be modified according to insert profile to ensure clearance • For user guide and accessories see pages 419-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Cutting depth maximum

(4) Minimum overhang

(5) WF(adapter)

For inserts, see pages: GIA-K (W=3-6) (298) • GIF (297) • GIF (full radius) (298) • GIF-E (W=4-6 full radius) (294) • GIF-E (W=4-6) (292) • GIM-C (521) • GIM-J (522)

• GIM-J-RA/LA (522) • GIM-UT (524) • GIM-UT-RA/LA (524) • GIM-W (523) • GIM-W-RA/LA (523) • GIMF (288) • GIMN (289) • GIMT (287) • GIMY (288)

• GIMY (full radius) (290) • GIMY-F (291) • GIP (297) • GIP (full radius) (296) • GIP-E (293) • GIP-E (full radius) (294) • GIP-UN (303) • GIPA (full radius W=3-6) (301)

• GIPA (W=3-6) (300) • GIPM-A46 / GIP-1250 (375) • GIPY (300) • GITM (299) • GITM (full radius) (299) • GPV (304) • TIP-MT (647) • TIP-P-BSPT (674)

• TIP-P-BSW (668) • TIP-P-ISO (658) • TIP-P-NPT (671) • TIP-P-UN (664) • TIP-WT (641)

Flow Rate vs. Pressure 70 Bar 100 Bar 140 Bar

Flow Rate (liters/min) Flow Rate (liters/min) Flow Rate (liters/min)

Designation

CGPAD 3R/L-T16-JHP 6-8 7-9 8-10

CGPAD 3R-T22-JHP 5-7 6-8 7-9

CGPAD 4R/L-T16-JHP 10-12 11-13 12-14

CGPAD 5R/L-T16-JHP 12-14 16-18 19-21

CGHN-S OHX

Single-Ended Blades for

External Machining CWN-CWX

CUTDIA=2xOHX H HF

OAL WB

Designation H CWN(1) CWX(2) OHN(3) OHX(4) HF OAL WB

51.00 2.40

CGHN 32-3S 32.0 2.80 4.00 10.0 19.0 24.8 53.00 3.20

CGHN 32-4S 56.00 4.00

CGHN 32-5S 32.0 3.50 5.00 12.0 21.0 24.8 56.00 5.20

CGHN 32-6S

32.0 4.40 6.40 12.0 25.0 24.8

32.0 5.50 6.40 12.0 25.0 24.8

• When using a double-ended insert, grooving depth is limited by the insert • For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Minimum overhang

(4) Maximum overhang

For inserts, see pages: GIA-K (W=3-6) (298) • GIF (297) • GIF (full radius) (298) • GIF-E (W=4-6 full radius) (294) • GIF-E (W=4-6) (292)

• GIM-C (521) • GIM-J (522) • GIM-J-RA/LA (522) • GIM-UT (524) • GIM-UT-RA/LA (524) • GIM-W (523) • GIM-W-RA/LA (523) • GIMF (288)

• GIMN (289) • GIMT (287) • GIMY (288) • GIMY (full radius) (290) • GIMY-F (291) • GIP (297) • GIP (full radius) (296) • GIP-E (293)

• GIP-E (full radius) (294) • GIPA (full radius W=3-6) (301) • GIPA (W=3-6) (300) • GIPM-A46 / GIP-1250 (375) • GIPY (300)

• GITM (299) • GITM (full radius) (299) • TIP-MT (647) • TIP-P-BSPT (674) • TIP-P-BSW (668) • TIP-P-ISO (658) • TIP-P-NPT (671)

• TIP-P-UN (664) • TIP-WT (641)

For holders, see pages: C#-TBU (623) • IM-TBU (633) • UBHCR/L (618)

282 ISCAR