Page 45 - ISCAR_ARTICLE_2020

P. 45

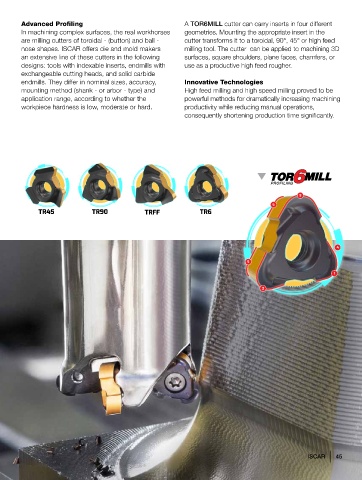

Advanced Profiling A TOR6MILL cutter can carry inserts in four different

In machining complex surfaces, the real workhorses geometries. Mounting the appropriate insert in the

are milling cutters of toroidal - (button) and ball - cutter transforms it to a toroidal, 90°, 45° or high feed

nose shapes. ISCAR offers die and mold makers milling tool. The cutter can be applied to machining 3D

an extensive line of these cutters in the following surfaces, square shoulders, plane faces, chamfers, or

designs: tools with indexable inserts, endmills with use as a productive high feed rougher.

exchangeable cutting heads, and solid carbide

endmills. They differ in nominal sizes, accuracy, Innovative Technologies

mounting method (shank - or arbor - type) and High feed milling and high speed milling proved to be

application range, according to whether the powerful methods for dramatically increasing machining

workpiece hardness is low, moderate or hard. productivity while reducing manual operations,

consequently shortening production time significantly.

3

6

TR45 TR90 TRFF TR6

4

5

1

2

ISCAR 45