Page 31 - Iscar Article 2_2017

P. 31

This method enables a noticeable reduction

in power consumption. It is no wonder that

trochoidal milling has been utilized successfully

in manufacturing parts with complicated slots

and grooves, such as blisks (bladed disks), blings

(bladed rings), impellers, etc., especially those with

relatively thin walls.

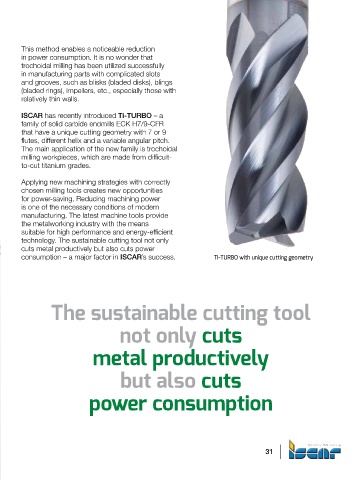

ISCAR has recently introduced Ti-TURBO – a

family of solid carbide endmills ECK H7/9-CFR

that have a unique cutting geometry with 7 or 9

flutes, different helix and a variable angular pitch.

The main application of the new family is trochoidal

milling workpieces, which are made from difficult-

to-cut titanium grades.

Applying new machining strategies with correctly

chosen milling tools creates new opportunities

for power-saving. Reducing machining power

is one of the necessary conditions of modern

manufacturing. The latest machine tools provide

the metalworking industry with the means

suitable for high performance and energy-efficient

technology. The sustainable cutting tool not only

cuts metal productively but also cuts power

consumption – a major factor in ISCAR’s success. TI-TURBO with unique cutting geometry

The sustainable cutting tool

not only cuts

metal productively

but also cuts

power consumption

31