Page 28 - Iscar Article 2_2017

P. 28

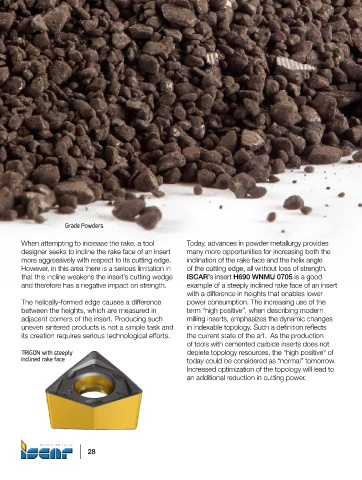

Grade Powders

When attempting to increase the rake, a tool Today, advances in powder metallurgy provides

designer seeks to incline the rake face of an insert many more opportunities for increasing both the

more aggressively with respect to its cutting edge. inclination of the rake face and the helix angle

However, in this area there is a serious limitation in of the cutting edge, all without loss of strength.

that this incline weakens the insert’s cutting wedge ISCAR’s insert H690 WNMU 0705 is a good

and therefore has a negative impact on strength. example of a steeply inclined rake face of an insert

with a difference in heights that enables lower

The helically-formed edge causes a difference power consumption. The increasing use of the

between the heights, which are measured in term “high positive”, when describing modern

adjacent corners of the insert. Producing such milling inserts, emphasizes the dynamic changes

uneven sintered products is not a simple task and in indexable topology. Such a definition reflects

its creation requires serious technological efforts. the current state of the art. As the production

of tools with cemented carbide inserts does not

TRIGON with steeply deplete topology resources, the “high positive“ of

inclined rake face today could be considered as “normal” tomorrow.

Increased optimization of the topology will lead to

an additional reduction in cutting power.

28