Page 30 - Iscar_Article_Brochure

P. 30

Turbine

Production

Process reliability throughout

the production chain

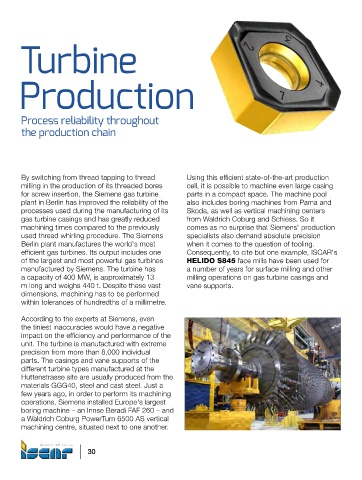

By switching from thread tapping to thread Using this efficient state-of-the-art production

milling in the production of its threaded bores cell, it is possible to machine even large casing

for screw insertion, the Siemens gas turbine parts in a compact space. The machine pool

plant in Berlin has improved the reliability of the also includes boring machines from Pama and

processes used during the manufacturing of its Skoda, as well as vertical machining centers

gas turbine casings and has greatly reduced from Waldrich Coburg and Schiess. So it

machining times compared to the previously comes as no surprise that Siemens' production

used thread whirling procedure. The Siemens specialists also demand absolute precision

Berlin plant manufactures the world's most when it comes to the question of tooling.

efficient gas turbines. Its output includes one Consequently, to cite but one example, ISCAR's

of the largest and most powerful gas turbines HELIDO S845 face mills have been used for

manufactured by Siemens. The turbine has a number of years for surface milling and other

a capacity of 400 MW, is approximately 13 milling operations on gas turbine casings and

m long and weighs 440 t. Despite these vast vane supports.

dimensions, machining has to be performed

within tolerances of hundredths of a millimetre.

According to the experts at Siemens, even

the tiniest inaccuracies would have a negative

impact on the efficiency and performance of the

unit. The turbine is manufactured with extreme

precision from more than 8,000 individual

parts. The casings and vane supports of the

different turbine types manufactured at the

Huttenstrasse site are usually produced from the

materials GGG40, steel and cast steel. Just a

few years ago, in order to perform its machining

operations, Siemens installed Europe's largest

boring machine – an Innse Beradi FAF 260 – and

a Waldrich Coburg PowerTurn 6500 AS vertical

machining centre, situated next to one another.

30