Page 32 - Iscar_Article_Brochure

P. 32

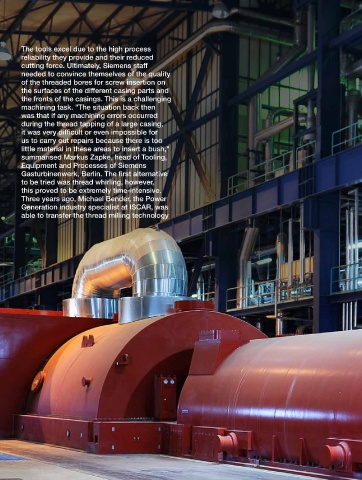

The tools excel due to the high process

reliability they provide and their reduced

cutting force. Ultimately, Siemens staff

needed to convince themselves of the quality

of the threaded bores for screw insertion on

the surfaces of the different casing parts and

the fronts of the casings. This is a challenging

machining task. "The situation back then

was that if any machining errors occurred

during the thread tapping of a large casing,

it was very difficult or even impossible for

us to carry out repairs because there is too

little material in these areas to insert a bush,"

summarised Markus Zapke, head of Tooling,

Equipment and Processes of Siemens

Gasturbinenwerk, Berlin. The first alternative

to be tried was thread whirling, however,

this proved to be extremely time-intensive.

Three years ago, Michael Bender, the Power

Generation industry specialist at ISCAR, was

able to transfer the thread milling technology

32