Page 222 - Threading_Handbook

P. 222

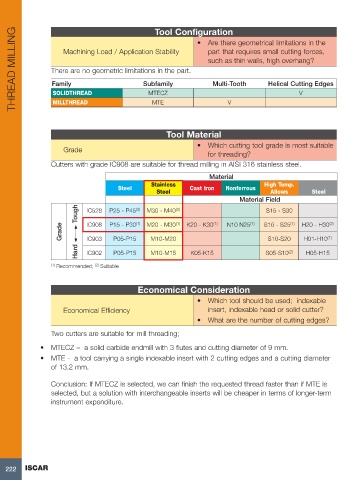

Tool Configuration

THREAD MILLING There are no geometric limitations in the part. • Are there geometrical limitations in the

Machining Load / Application Stability

part that requires small cutting forces,

such as thin walls, high overhang?

Family

Multi-Tooth

Subfamily

Helical Cutting Edges

V

SOLIDTHREAD

MTECZ

MTE

MILLTHREAD

V

Tool Material

• Which cutting tool grade is most suitable

Grade

for threading?

Cutters with grade IC908 are suitable for thread milling in AISI 316 stainless steel.

Material

Stainless High Temp.

Steel Cast Iron Nonferrous

Steel Allows Steel

Material Field

Tough IC528 P25 - P45 (2) M30 - M40 (2) (1) (1) S15 - S30 (1) (2)

(1)

(1)

Grade IC908 P15 - P30 M20 - M30 K20 - K30 N10 N25 S10 - S25 H20 - H30 (1)

H01-H10

IC903

S10-S20

M10-M20

P05-P15

Hard IC902 P05-P15 M10-M15 K05-K15 S05-S10 (2) H05-H15

(2)

(1) Recommended; Suitable

Economical Consideration

• Which tool should be used; indexable

Economical Efficiency insert, indexable head or solid cutter?

• What are the number of cutting edges?

Two cutters are suitable for mill threading;

• MTECZ – a solid carbide endmill with 3 flutes and cutting diameter of 9 mm.

• MTE - a tool carrying a single indexable insert with 2 cutting edges and a cutting diameter

of 13.2 mm.

Conclusion: If MTECZ is selected, we can finish the requested thread faster than if MTE is

selected, but a solution with interchangeable inserts will be cheaper in terms of longer-term

instrument expenditure.

222 ISCAR