Page 119 - HOLE_MAKING_CATALOG_INCH_2022_P237-P372

P. 119

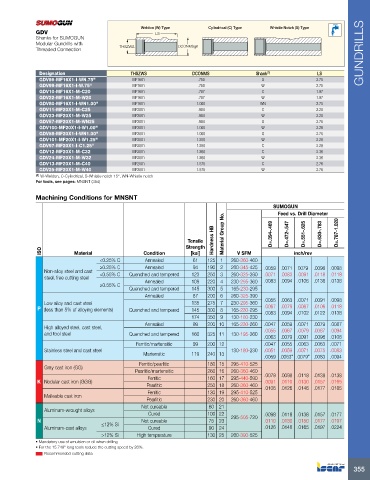

GDV Weldon (W) Type Cylindrical (C) Type Whistle Notch (S) Type

LS

Shanks for SUMOGUN

Modular Gundrills with THSZWS DCONMSg6

Threaded Connection GUNDRILLS

Designation THSZWS DCONMS Shank (1) LS

GDV56-MF16X1-I-WN.75" MF16X1 .750 S 2.75

GDV99-MF16X1-I-W.75" MF16X1 .750 W 2.75

GDV10-MF16X1-M-C20 MF16X1 .787 C 1.97

GDV22-MF16X1-M-W20 MF16X1 .787 W 1.97

GDV80-MF16X1-I-WN1.00" MF16X1 1.000 WN 2.75

GDV11-MF20X1-M-C25 MF20X1 .984 C 2.20

GDV23-MF20X1-M-W25 MF20X1 .984 W 2.20

GDV57-MF20X1-M-WN25 MF20X1 .984 S 2.76

GDV100-MF20X1-I-W1.00" MF20X1 1.000 W 2.28

GDV58-MF20X1-I-WN1.00" MF20X1 1.000 S 2.75

GDV101-MF20X1-I-W1.25" MF20X1 1.250 W 2.28

GDV97-MF20X1-I-C1.25" MF20X1 1.250 C 2.28

GDV12-MF20X1-M-C32 MF20X1 1.260 C 2.36

GDV24-MF20X1-M-W32 MF20X1 1.260 W 2.36

GDV13-MF20X1-M-C40 MF20X1 1.575 C 2.76

GDV25-MF20X1-M-W40 MF20X1 1.575 W 2.76

(1) W-Weldon, C-Cylindrical, S-Whistle notch 15°, WN-Whistle notch

For tools, see pages: MNSNT (354)

Machining Conditions for MNSNT

SUMOGUN

Feed vs. Drill Diameter

Tensile Hardness HB Material Group No. D=.394-.469 D=.472-.547 D=.551-.625 D=.630-.783 D=.787-1.020

Strength

ISO Material Condition [ksi] V SFM inch/rev

<0.25% C Annealed 61 125 1 260-360-460

≥0.25% C Annealed 94 190 2 260-345-425 .0059 .0071 0079 .0098 .0098

Non-alloy steel and cast

steel, free cutting steel <0.55% C Quenched and tempered 123 250 3 260-325-390 .0071 .0083 .0091 .0118 .0118

.0083 .0094 .0106 .0138 .0138

220 4

109

Annealed

230-295-360

≥0.55% C

Quenched and tempered 145 300 5 165-230-295

Annealed 87 200 6 260-325-390

Low alloy and cast steel 135 275 7 230-295-360 .0055 .0063 .0071 .0091 .0098

P (less than 5% of alloying elements) Quenched and tempered 145 300 8 165-230-295 .0067 .0079 .0087 .0106 .0118

.0083 .0094 .0102 .0122 .0138

174 350 9 130-180-230

Annealed 99 200 10 165-230-260 .0047 .0059 .0071 .0079 .0087

High alloyed steel, cast steel, .0055 .0067 .0079 .0087 .0094

and tool steel Quenched and tempered 160 325 11 130-195-260

.0063 .0079 .0091 .0098 .0106

Ferritic/martensitic 99 200 12 .0047 .0055 .0063 .0063 .0071

Stainless steel and cast steel 130-180-230 .0051 .0059 .0071 .0075 .0083

Martensitic 119 240 13

.0059 .0063" .0079" .0083 .0094

Ferritic/pearlitic 180 15 295-410-525

Gray cast iron (GG)

Pearlitic/martensitic 260 16 260-360-460

Ferritic 160 17 295-440-590 .0079 .0098 .0118 .0138 .0138

K Nodular cast iron (GGG) .0091 .0110 .0130 .0157 .0165

Pearlitic 250 18 260-360-460 .0106 .0126 .0146 .0177 .0185

Ferritic 130 19 295-410-525

Malleable cast iron

Pearlitic 230 20 260-360-460

Not cureable 60 21

Aluminum-wrought alloys

Cured 100 22 .0098 .0118 .0138 .0157 .0177

N ≤12% Si Not cureable 75 23 295-505-720 .0110 .0130 .0150 .0177 .0197

Aluminum-cast alloys Cured 90 24 .0126 .0146 .0165 .0197 .0224

>12% Si High temperature 130 25 260-390-525

• Mandatory use of emulsion or oil when drilling

• For the 15.748” long tools reduce the cutting speed by 20%.

Recommended cutting data

355