Page 21 - HOLE_MAKING_CATALOG_INCH_2022_P373-P446

P. 21

USER GUIDE

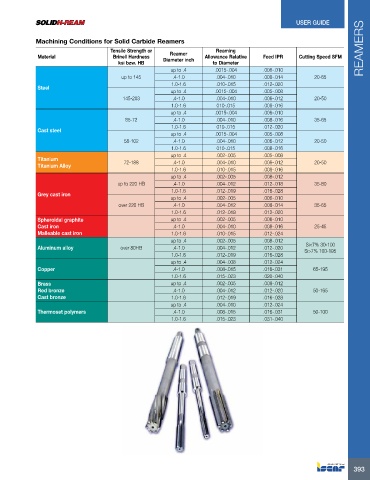

Machining Conditions for Solid Carbide Reamers

Tensile Strength or Reaming REAMERS

Reamer

Material Brinell Hardness Diameter inch Allowance Relative Feed IPR Cutting Speed SFM

ksi bzw. HB to Diameter

up to .4 .0015-.004 .006-.010

up to 145 .4-1.0 .004-.010 .008-.014 20-65

1.0-1.6 .010-.015 .012-.020

Steel

up to .4 .0015-.004 .005-.008

145-203 .4-1.0 .004-.010 .006-.012 20-50

1.0-1.6 010-.015 .008-.016

up to .4 .0015-.004 .006-.010

85-72 .4-1.0 .004-.010 .008-.016 35-65

1.0-1.6 010-.015 .012-.020

Cast steel

up to .4 .0015-.004 .005-.008

58-102 .4-1.0 .004-.010 .006-.012 20-50

1.0-1.6 010-.015 .008-.016

up to .4 .002-.005 .005-.008

Titanium

Titanium Alloy 72-188 .4-1.0 .004-.010 .006-.012 20-50

1.0-1.6 .010-.015 .008-.016

up to .4 .002-.005 .008-.012

up to 220 HB .4-1.0 .004-.012 .012-.018 35-80

1.0-1.6 .012-.019 .016-.028

Grey cast iron

up to .4 .002-.005 .006-.010

over 220 HB .4-1.0 .004-.012 .008-.014 35-65

1.0-1.6 .012-.019 .012-.020

Spheroidal graphite up to .4 .002-.005 .006-.010

Cast iron .4-1.0 .004-.010 .008-.016 25-45

Malleable cast iron 1.0-1.6 .010-.015 .012-.024

up to .4 .002-.005 .008-.012

Si<7% 30-100

Aluminum alloy over 80HB .4-1.0 .004-.012 .012-.020 Si>7% 100-195

1.0-1.6 .012-.019 .016-.028

up to .4 .004-.008 .012-.024

Copper .4-1.0 .008-.015 .016-.031 65-195

1.0-1.6 .015-.023 .020-.040

Brass up to .4 .002-.005 .008-.012

Red bronze .4-1.0 .004-.012 .012-.020 50-165

Cast bronze 1.0-1.6 .012-.019 .016-.028

up to .4 .004-.010 .012-.024

Thermoset polymers .4-1.0 .008-.015 .016-.031 50-100

1.0-1.6 .015-.023 .031-.040

393