Page 35 - HOLE_MAKING_CATALOG_INCH_2022_P373-P446

P. 35

USER GUIDE

REAMERS

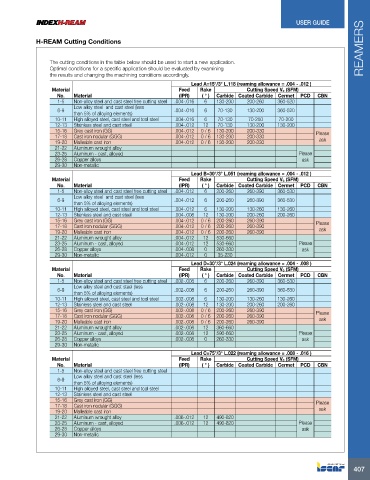

H-REAM Cutting Conditions

The cutting conditions in the table below should be used to start a new application.

Optimal conditions for a specific application should be evaluated by examining

the results and changing the machining conditions accordingly.

Lead A=15°/3° L.118 (reaming allowance = .004 - .012 )

Material Feed Rake Cutting Speed Vc (SFM)

No. Material (IPR) ( ° ) Carbide Coated Carbide Cermet PCD CBN

1-5 Non-alloy steel and cast steel free cutting steel .004-.016 6 130-200 200-260 360-520

Low alloy steel and cast steel (less

6-9 .004-.016 6 70-130 130-200 360-520

than 5% of alloying elements)

10-11 High alloyed steel, cast steel and tool steel .004-.016 6 70-130 70-200 70-200

12-13 Stainless steel and cast steel .004-.012 12 70-130 130-200 130-200

15-16 Grey cast iron (GG) .004-.012 0 / 6 130-200 200-330 Please

17-18 Cast iron nodular (GGG) .004-.012 0 / 6 130-200 200-330

19-20 Malleable cast iron .004-.012 0 / 6 130-200 200-330 ask

21-22 Aluminum wrought alloy

23-25 Aluminum - cast, alloyed Please

26-28 Copper alloys ask

29-30 Non-metallic

Lead B=30°/3° L.051 (reaming allowance = .004 - .012 )

Material Feed Rake Cutting Speed Vc (SFM)

No. Material (IPR) ( ° ) Carbide Coated Carbide Cermet PCD CBN

1-5 Non-alloy steel and cast steel free cutting steel .004-.012 6 200-260 260-390 360-530

Low alloy steel and cast steel (less

6-9 .004-.012 6 200-260 260-390 360-530

than 5% of alloying elements)

10-11 High alloyed steel, cast steel and tool steel .004-.012 6 130-200 130-260 130-260

12-13 Stainless steel and cast steel .004-.008 12 130-200 200-260 200-260

15-16 Grey cast iron (GG) .004-.012 0 / 6 200-260 260-390 Please

17-18 Cast iron nodular (GGG) .004-.012 0 / 6 200-260 260-390

19-20 Malleable cast iron .004-.012 0 / 6 200-260 260-390 ask

21-22 Aluminum wrought alloy .004-.012 12 530-660

23-25 Aluminum - cast, alloyed .004-.012 12 530-660 Please

26-28 Copper alloys .004-.008 0 260-330 ask

29-30 Non-metallic .004-.012 0 35-230

Lead D=30°/3° L.024 (reaming allowance = .004 - .008 )

Material Feed Rake Cutting Speed Vc (SFM)

No. Material (IPR) ( ° ) Carbide Coated Carbide Cermet PCD CBN

1-5 Non-alloy steel and cast steel free cutting steel .002-.008 6 200-260 260-390 360-530

Low alloy steel and cast steel (less

6-9 .002-.008 6 200-260 260-390 360-530

than 5% of alloying elements)

10-11 High alloyed steel, cast steel and tool steel .002-.008 6 130-200 130-260 130-260

12-13 Stainless steel and cast steel .002-.008 12 130-200 200-260 200-260

15-16 Grey cast iron (GG) .002-.008 0 / 6 200-260 260-390 Please

17-18 Cast iron nodular (GGG) .002-.008 0 / 6 200-260 260-390 ask

19-20 Malleable cast iron .002-.008 0 / 6 200-260 260-390

21-22 Aluminum wrought alloy .002-.008 12 360-660

23-25 Aluminum - cast, alloyed .002-.008 12 590-660 Please

26-28 Copper alloys .002-.008 0 260-330 ask

29-30 Non-metallic

Lead C=75°/3° L.022 (reaming allowance = .008 - .016 )

Material Feed Rake Cutting Speed Vc (SFM)

No. Material (IPR) ( ° ) Carbide Coated Carbide Cermet PCD CBN

1-5 Non-alloy steel and cast steel free cutting steel

Low alloy steel and cast steel (less

6-9

than 5% of alloying elements)

10-11 High alloyed steel, cast steel and tool steel

12-13 Stainless steel and cast steel

15-16 Grey cast iron (GG) Please

17-18 Cast iron nodular (GGG)

19-20 Malleable cast iron ask

21-22 Aluminum wrought alloy .006-.012 12 490-820

23-25 Aluminum - cast, alloyed .006-.012 12 490-820 Please

26-28 Copper alloys ask

29-30 Non-metallic

407