Page 40 - HOLE_MAKING_CATALOG_INCH_2022_P373-P446

P. 40

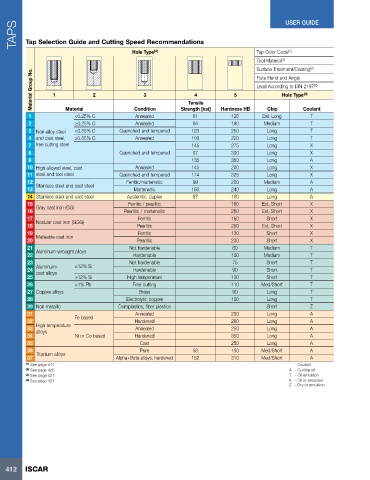

TAPS Tap Selection Guide and Cutting Speed Recommendations USER GUIDE

Hole Type (4) Tap Color Code (1)

Tool Material (1) (2)

Surface Treatment/Coating

Material Group No. 1 2 3 Tensile 5 Flute Hand and Angle (4) (3)

Lead According to DIN 2197

4

Hole Type

Chip

Annealed

61

<0.25% C

125

T

1 Material Condition Strength [ksi] Hardness HB Ext. Long Coolant

2 ≥0.25% C Annealed 94 190 Medium T

3 Non-alloy steel <0.55% C Quenched and tempered 123 250 Long T

4 and cast steel, ≥0.55% C Annealed 109 220 Long T

7 free cutting steel 145 275 Long X

8 Quenched and tempered 87 300 Long X

9 135 350 Long A

10 High alloyed steel, cast Annealed 145 200 Long X

11 steel and tool steel Quenched and tempered 174 325 Long X

12 Stainless steel and cast steel Ferritic/martensitic 99 200 Medium A

13 Martensitic 160 240 Long A

14 Stainless steel and cast steel Austenitic, duplex 87 180 Long A

15 Gray cast iron (GG) Ferritic / pearlitic 180 Ext. Short X

16 Pearlitic / martensitic 260 Ext. Short X

17 Nodular cast iron (GGG) Ferritic 160 Short X

18 Pearlitic 250 Ext. Short X

19 Ferritic 130 Short X

20 Malleable cast iron Pearlitic 230 Short X

21 Not hardenable 60 Medium T

22 Aluminum-wrought alloys Hardenable 100 Medium T

23 Not hardenable 75 Short T

24 Aluminum- ≤12% Si Hardenable 90 Short T

cast alloys

25 >12% Si High temperature 130 Short T

26 >1% Pb Free cutting 110 Med/Short T

27 Copper alloys Brass 90 Long T

28 Electrolytic copper 100 Long T

29 Non metallic Duroplastics, fiber plastics Short Z

31 Annealed 200 Long A

32 Fe based Hardened 280 Long A

33 High temperature Annealed 250 Long A

alloys

34 Ni or Co based Hardened 350 Long A

35 Cast 250 Long A

36 Titanium alloys Pure 58 190 Med/Short A

37 Alpha+Beta alloys, hardened 152 310 Med/Short A

(1) See page 411 Coolant

(2) See page 426 A - Cutting oil

(3) See page 427 T - Oil emulsion

(4) See page 427 X - Oil or emulsion

Z - Dry or emulsion

412 ISCAR