Page 97 - MILLING_CATALOG_INCH_2022_P229-P360

P. 97

OAL

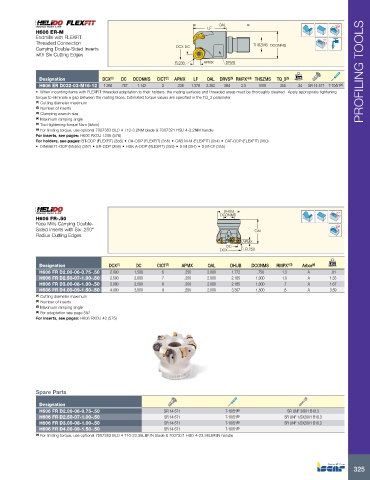

H606 ER-M LF

Endmills with FLEXFIT

Threaded Connection THSZMS DCONMS Rd°

Carrying Double-Sided Inserts DCX DC

with Six Cutting Edges

R.236 APMX DRVS

Lbs PROFILING TOOLS

Designation DCX (1) DC DCONMS CICT (2) APMX LF OAL DRVS (3) RMPX° (4) THSZMS TQ_3 (5)

H606 ER D032-03-M16-12 1.260 .787 1.142 3 .236 1.378 2.362 .984 2.5 M16 355 .34 SR 14-571 T-10/51 (a)

• When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and threaded areas must be thoroughly cleaned. Apply appropriate tightening

torque to eliminate a gap between the mating faces. Estimated torque values are specified in the TQ_3 parameter

(1) Cutting diameter maximum

(2) Number of inserts

(3) Clamping wrench size

(4) Maximum ramping angle

(5) Tool tightening torque Nxm (lbfxin)

(a) For limiting torque, use optional 7007383 BLD 4 T10-3.2NM blade & 7007321 HSD 4-3.2NM handle

For inserts, see pages: H606 RXCU 1206 (576)

For holders, see pages: BT-ODP (FLEXFIT) (356) • C#-ODP (FLEXFIT) (356) • CAB M-M (FLEXFIT) (354) • CAT-ODP (FLEXFIT) (360)

• DIN69871-ODP (Metric) (357) • ER-ODP (358) • HSK A-ODP (FLEXFIT) (359) • S M (354) • S M-CF (355)

DHUB Rd°

H606 FR-.50 DCONMS

Face Mills Carrying Double-

Sided Inserts with Six .250" OAL

Radius Cutting Edges

APMX

DC

DCX R.250

Designation DCX (1) DC CICT (2) APMX OAL DHUB DCONMS RMPX° (3) Arbor (4) Lbs

H606 FR D2.00-06-0.75-.50 2.000 1.500 6 .250 2.000 1.772 .750 1.3 A .81

H606 FR D2.50-07-1.00-.50 2.500 2.000 7 .250 2.000 2.165 1.000 1.0 A 1.33

H606 FR D3.00-08-1.00-.50 3.000 2.500 8 .250 2.000 2.165 1.000 .7 A 1.67

H606 FR D4.00-09-1.50-.50 4.000 3.500 9 .250 2.000 3.307 1.500 .6 A 3.59

(1) Cutting diameter maximum

(2) Number of inserts

(3) Maximum ramping angle

(4) For adaptation see page 592

For inserts, see pages: H606 RXCU 43 (575)

Spare Parts

Designation

H606 FR D2.00-06-0.75-.50 SR 14-571 T-10/51 (a) SR UNF 3/8X1 B18.3

H606 FR D2.50-07-1.00-.50 SR 14-571 T-10/51 (a) SR UNF 1/2X20X1 B18.3

H606 FR D3.00-08-1.00-.50 SR 14-571 T-10/51 (a) SR UNF 1/2X20X1 B18.3

H606 FR D4.00-09-1.50-.50 SR 14-571 T-10/51 (a)

(a) For limiting torque, use optional 7007383 BLD 4 T10-23.38LBF.IN blade & 7007321 HSD 4-23.38LBF.IN handle

325