Page 99 - MILLING_CATALOG_INCH_2022_P229-P360

P. 99

USER GUIDE

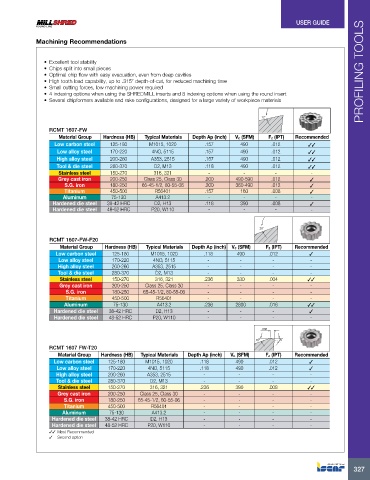

Machining Recommendations

• Excellent tool stability

• Chips split into small pieces

• Optimal chip flow with easy evacuation, even from deep cavities PROFILING TOOLS

• High tooth load capability, up to .315” depth-of-cut, for reduced machining time

• Small cutting forces, low machining power required

• 4 indexing options when using the SHREDMILL inserts and 8 indexing options when using the round insert

• Several chipformers available and rake configurations, designed for a large variety of workpiece materials

12˚

RCMT 1607-FW

Material Group Hardness (HB) Typical Materials Depth Ap (inch) Vc (SFM) Fz (IPT) Recommended

Low carbon steel 125-180 M1015, 1020 .157 490 .012 33

Low alloy steel 170-220 4NO, 5115 .157 490 .012 33

High alloy steel 200-260 A353, 2515 .157 490 .012 33

Tool & die steel 280-370 D2, M13 .118 490 .012 33

Stainless steel 150-270 316, 321 - - - -

Grey cast iron 200-250 Class 25, Class 30 .200 490-590 .012 3

S.G. iron 180-250 65-45-1/2, 80-55-06 .200 360-490 .012 3

Titanium 450-500 R56401 .157 160 .008 3

Aluminum 75-130 A413.2 - - - -

Hardened die steel 38-42 HRC D2, H13 .118 390 .008 3

Hardened die steel 48-52 HRC P20, W110 - - - -

20˚

RCMT 1607-FW-F20

Material Group Hardness (HB) Typical Materials Depth Ap (inch) Vc (SFM) Fz (IPT) Recommended

Low carbon steel 125-180 M1015, 1020 .118 490 .012 3

Low alloy steel 170-220 4NO, 5115 - - - -

High alloy steel 200-260 A353, 2515 - - - -

Tool & die steel 280-370 D2, M13 - - - -

Stainless steel 150-270 316, 321 .236 330 .004 33

Grey cast iron 200-250 Class 25, Class 30 - - - -

S.G. iron 180-250 65-45-1/2, 80-55-06 - - - -

Titanium 450-500 R56401 - - - -

Aluminum 75-130 A413.2 .236 2800 .016 33

Hardened die steel 38-42 HRC D2, H13 - - - 3

Hardened die steel 48-52 HRC P20, W110 - - - -

.006

20˚ 20˚

RCMT 1607 FW-T20

Material Group Hardness (HB) Typical Materials Depth Ap (inch) Vc (SFM) Fz (IPT) Recommended

Low carbon steel 125-180 M1015, 1020 .118 490 .012 3

Low alloy steel 170-220 4NO, 5115 .118 490 .012 3

High alloy steel 200-260 A353, 2515 - - - -

Tool & die steel 280-370 D2, M13 - - - -

Stainless steel 150-270 316, 321 .236 390 .008 33

Grey cast iron 200-250 Class 25, Class 30 - - - -

S.G. iron 180-250 65-45-1/2, 80-55-06 - - - -

Titanium 450-500 R56401 - - - -

Aluminum 75-130 A413.2 - - - -

Hardened die steel 38-42 HRC D2, H13 - - - -

Hardened die steel 48-52 HRC P20, W110 - - - -

33 Most Recommended

3 Second option

327